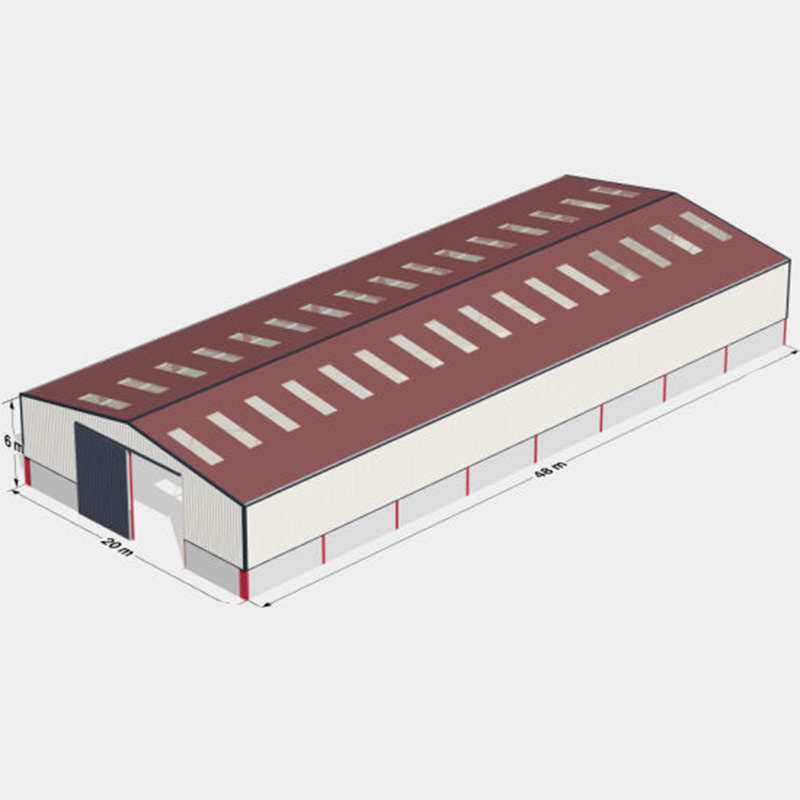

Cheap PriceList for Warehouse Homes - Low price Metal building construction design large span single two story steel structure warehouse building – Vanhe

Cheap PriceList for Warehouse Homes - Low price Metal building construction design large span single two story steel structure warehouse building – Vanhe Detail:

1.Installation

Our new type steel structure is more convenient to install, 2,000 square meters can be completed within 1 week by 5 workers.

1) The main steel frames(structure) are all connected by high-strength bolts, no need on-site welding. Its’ installation is similar to building blocks.

(2) Totally 2 types of purlins will be used on roof and the walls of our Steel Structure. (there are at least 4 types of purlins will be used on the roofing and walls by other manufacturers.) So it can be constructed more easily without further distinction.

(3) The combination of Chemical bolt and chemical glue bans the complex steel cage foundation structure in traditional steel structures, making on-site construction more convenient. The columns are easier to align so that the steel structures are at the same level.

(4) The architectural installation drawings are easier to understand and can be installed in conjunction with theinstallation video, reducing the cost of assignments.

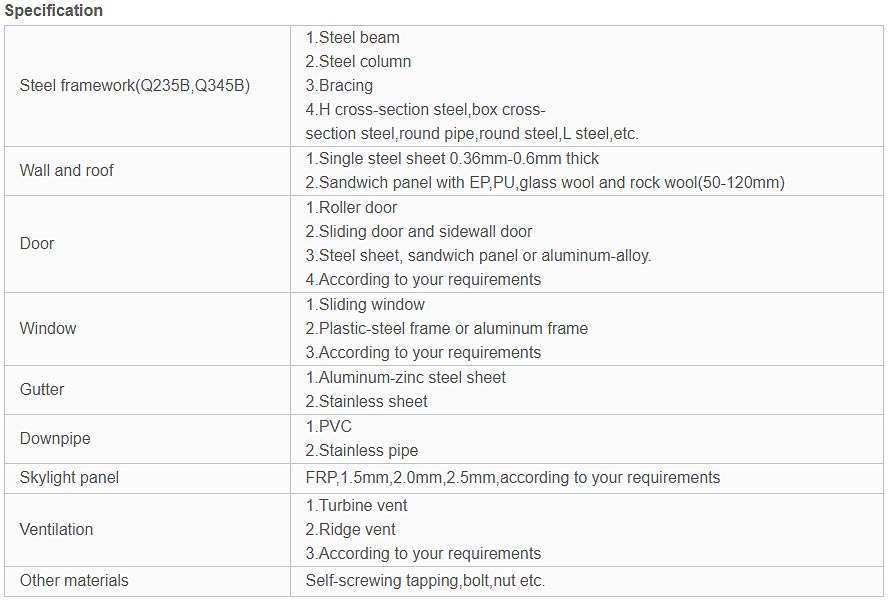

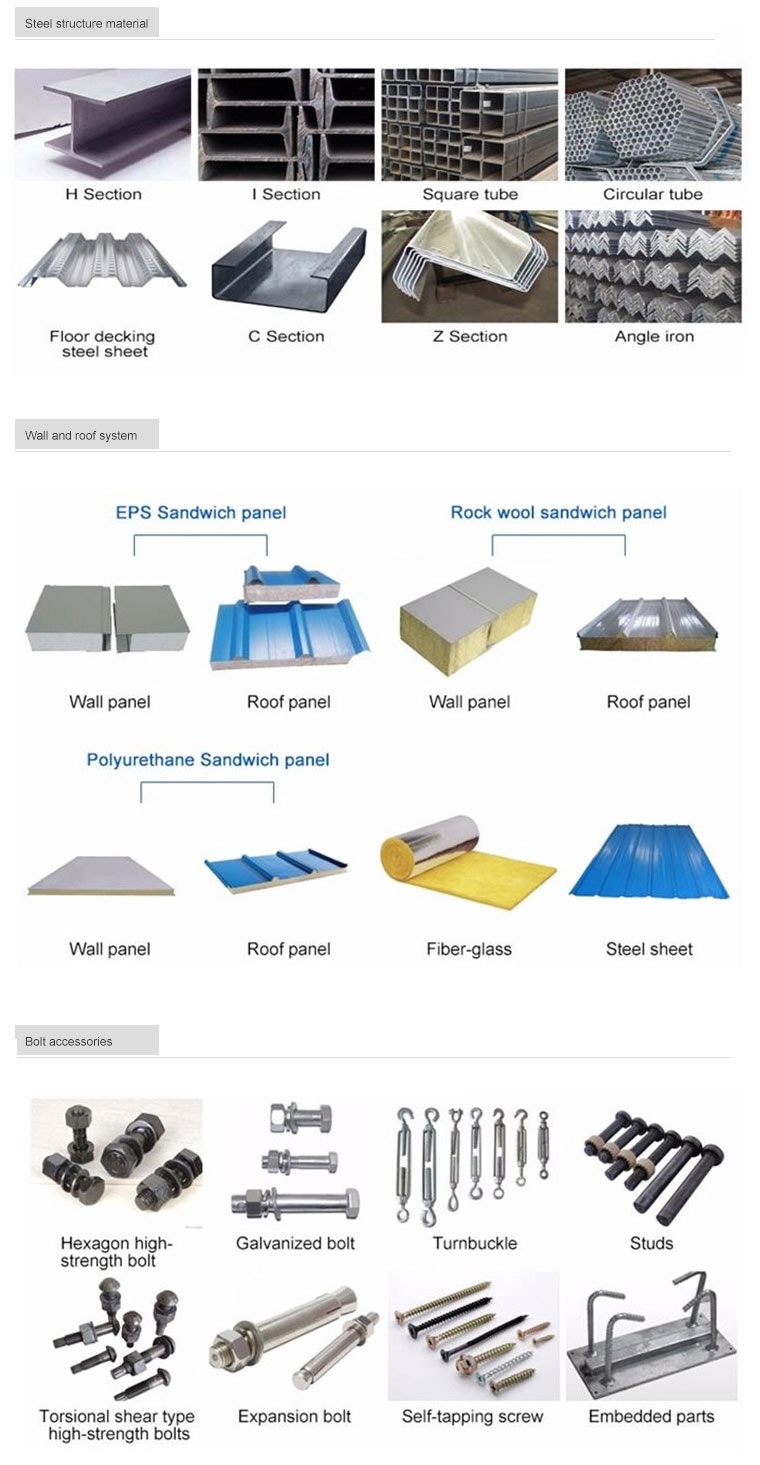

Materials:

1. The main frame (columns and beams) is made of welded H-style steel.

2. The columns are connected with the foundation by pre-embedding anchor bolt.

3. The beams and columns, beams and beams are connected with high intensity bolts.

4. The envelope construction net is made of cold form C-style purlins.

5. The wall and roof are made of color steel board or color steel sandwich panels, which are connected with the purlin by Self-tapping nails.

6. Doors and windows can be designed at anywhere which can be made into normal type, sliding type or roll up type with material of PVC, metal, alloy aluminum, sandwich panel and so on.

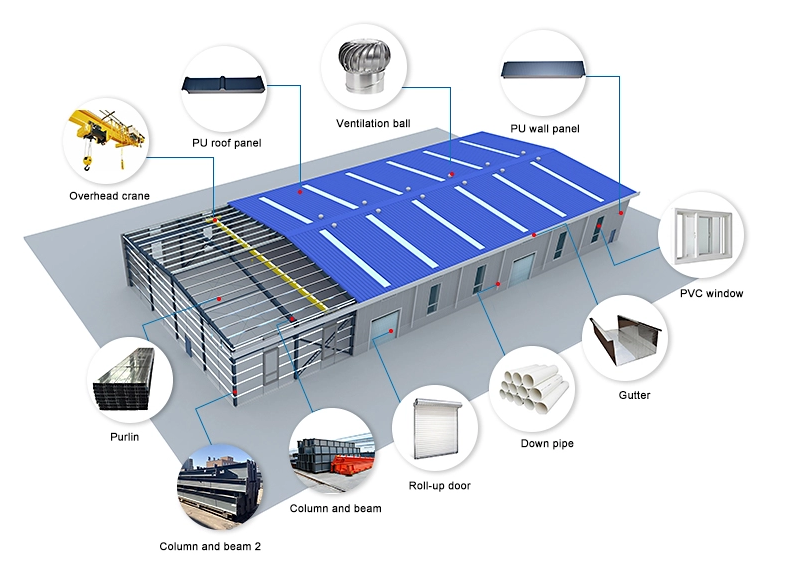

2.Overseas Project

(Over than 2000+projects)

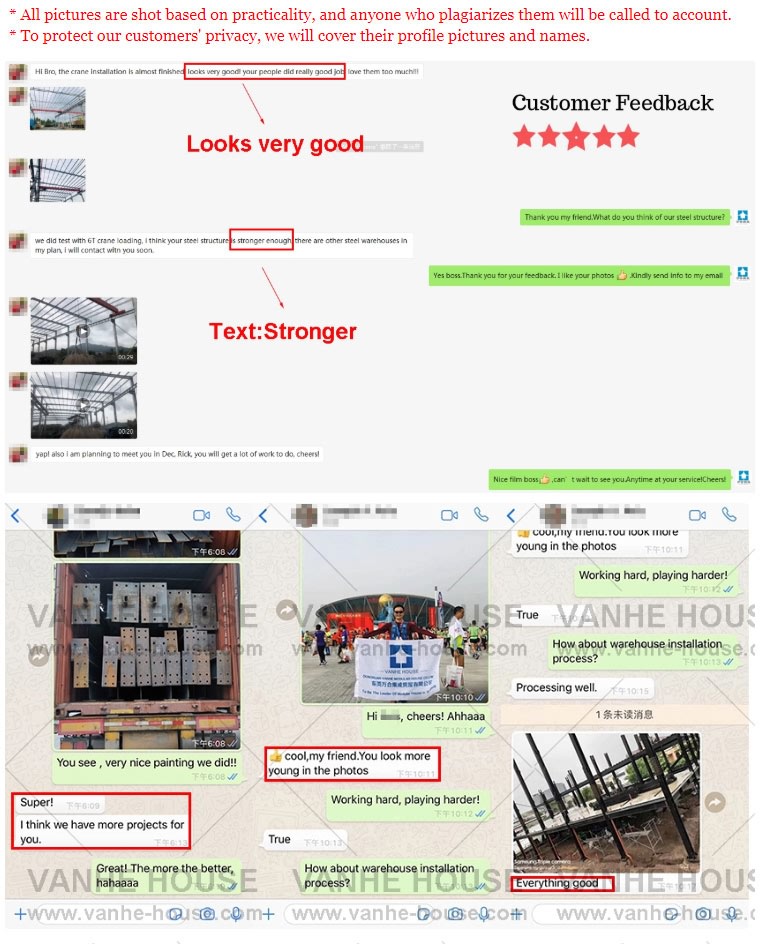

3.Steel Structure Customer Feedback

4.ADVANTAGES

1.Professional and efficient designer teams

2.Collectivize and large-scale production

3.Professional and efficient installation of the construction

4.International quality control system

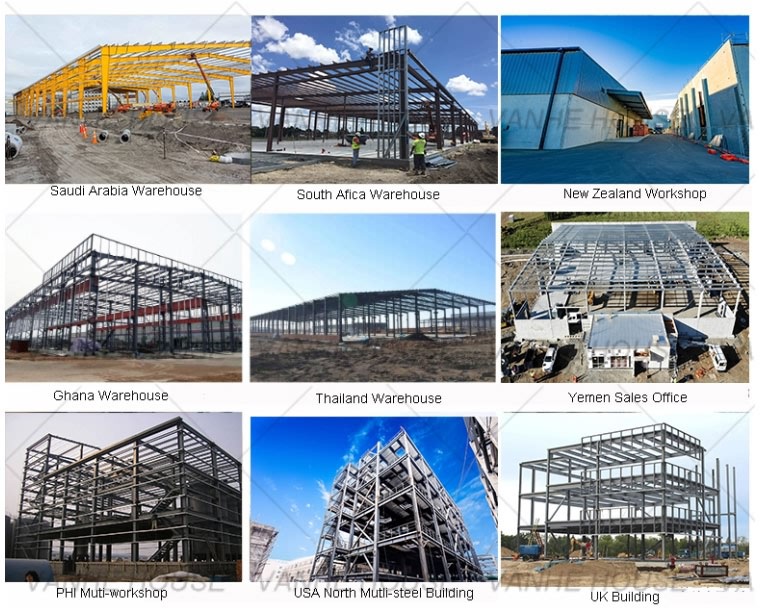

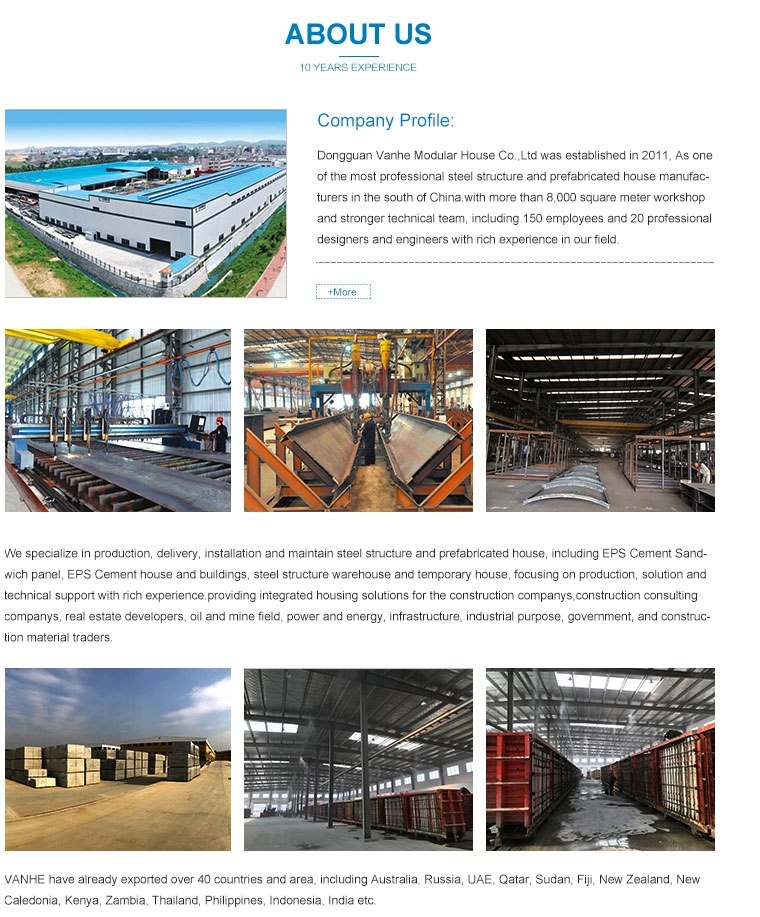

5.Company

Products & Service Scope:

Design& Engineering service, steel building, space frames, portable cabins, tubular steel structures, basic building elements (built-up welded H-section, hot-rolled H-section, channel, steel column, steel beam), standard frames, secondary framing, roof & wall materials, temp-con (sandwich) panels

Market:

Over 16000 buildings delivered in the world!

Products have been exported to Europe, Australia, North America, the Middle East, Africa, Asia and other countries and regions.

6.Packaging&Delivery

Product detail pictures:

Related Product Guide:

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for Cheap PriceList for Warehouse Homes - Low price Metal building construction design large span single two story steel structure warehouse building – Vanhe , The product will supply to all over the world, such as: Algeria, Netherlands, Johannesburg, Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

How to Buy a VHCON Prefab House?

Step 1: Initial Enquiry or Display Hall Visit

Start by contacting the VHCON sales team for a no-obligation chat about your project. We’ll walk you through the options, answer any questions, and explain what’s involved with owning a VHCON Modular House.

You can also book a private tour at our Display Hall to view our houses in person.

Whether you’re still planning or ready to move ahead, this first step is all about giving you clarity, confidence, and expert advice from the start.

Step 2: Site Suitability & Pre-Approval Check

Once you’re ready to proceed, we’ll connect you with our trusted Building Certifier and Structural Engineer for a preliminary assessment. Alternatively you can provide your own preliminary assessment from a town planner or building certifier to assess eligibility.

You will need to provide your own site plan to conduct a preliminary assessment. This preliminary assessment helps identify any potential planning restrictions, zoning issues, or site challenges early on — such as setbacks, overlays, wind speed, and climate zone.

This step ensures you have confidence that your project is likely to meet council and building code requirements before moving further into the approvals process.

Step 3: Contract Signing & Initial Deposit

Once your site has been deemed suitable and you’re ready to move forward, we’ll prepare your Build Contract.

This contract will outline:

- The scope of works and what’s included in your Expander Home package

- Customisations (if any) and your selected finishes

- Estimated timeframes for manufacturing, delivery, and installation

- Payment terms, including deposit and progress payments

To secure your place in our production schedule, a non-refundable initial deposit is required upon signing. This deposit confirms your commitment and allows us to begin the next steps — including final plans, engineering, and scheduling your batch build.

Note: We’ll ensure you have ample time to review and understand all contract details, and we’re here to answer any questions before you sign.

Step 4: Factory Construction

Once your contract is finalised, your home enters our scheduled production process. Built in controlled factory conditions by our trusted manufacturing partners, this approach ensures consistent quality, weather protection, and reliable delivery timelines.

The Express Portables design team oversees all aspects of compliance, workmanship, and detail throughout the build. Construction typically takes 9–11 weeks to complete.

Step 5: Shipping, Transport & Delivery

Once factory construction is complete, your home is carefully prepared for shipment. International shipping from our manufacturing facility typically takes 4–5 weeks.

Transport to your site is scheduled in coordination with you or your site builder. Your builder is responsible for unloading the building onto the prepared footings and beginning the installation process.

After installation, the customer is required to arrange the final Occupancy Certificate, with guidance and support provided by our Building Certifier to ensure a smooth approval process.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.