Factory best selling Cheap Prefab Cabins - China Supply Sale Low Cost Prices Portable Live Homes Prefabricated Houses – Vanhe

Factory best selling Cheap Prefab Cabins - China Supply Sale Low Cost Prices Portable Live Homes Prefabricated Houses – Vanhe Detail:

Specification:

| Product Name | Modular houses – K-style |

| Column | 80# C style steel |

| Ground beam | 80# C style steel |

| Floor beam | 80# C style steel and 50# C style steel joint together (for 2 storey house only) |

| Secondary floor beam | 80# C style steel (for 2 storey house only) |

| Roof | 80# C style steel welding as truss & 40# angle steel as purlin |

| Wall panel | 50/75/100mm thick EPS/Glass wool/Rock wool/Propor/PU sandwich panel |

| Roof tile | 30/50/75/100mm thick corrugated EPS… sandwich panel / corrugated steel sheet / steel glazed tile |

| Corridor | steel plate (for 2 storey house only) |

| Floor | Hengxin light magnesium board or plywood |

| Window | UPVC or aluminum sliding window with fly screen, shutter window |

| Door | aluminum frame with panel same , security door including lock |

| Ceiling | plaster board ceiling, PVC ceiling, 50mm/75mm thick EPS/rock wool/PU sandwich panel |

| Steel structure | anti-rust, painted. Include rivet, screw |

| Joint material | steel column/aluminum alloy |

| Veranda, Garage and fence can be customized as required. | |

Technical data:

* Roof load: 0.3kn/m2

* Floor load:1.5kn/m2

* Wind load: 0.3kn/m2, equal to against level 10 typhoon

* Earthquake resistance: magnitude- 7 earthquake

Note: If the criteria were exceeded, it can also load by reinforcing the structure.

Feature:

* Long lift span capacity with 15-20 years

* Prefabrication: easy to install and disassemble

* Lightness, easy to storage, transport and re-locate

* Low cost & Eco-friendly: using several times and recycling, economy and environment friendly

* Wide Application: living house, office, accommodation at construction site, out door temporary residence, also used as school and shop etc.

| The Parameters Of Villa | |

| 1 | Roof panels:double sided color sandwich big wave tiles,a level anti-fire resistance,heat preserved phenolic ceilings. |

| 2 | Wall panel:500mm double sided color steel sandwich phenolic board,substrate thickness is 0.326mm |

| 3 | Floor:A level anti-fire– high density fiber compound floor |

| 4 | Bases structure:Q235 bottom frame and 10# groove steel |

| 5 | Corner column:Q235 corner column and L100 angle steel |

| The Advantages Of Villa | |

| 1 | Structure:stable,anti-wind,anti-earthquake well,has great tightness and sound insulation effect |

| 2 | Assemble:lower demand for bases,assemble and disassemble conveniently,into and exit easily,hoisting process faster and installation process shorter. |

| 3 | Cost: cheaper and without loss |

| 4 | Appearance:appearance pretty,high degree and beatiful,benfit for improve enterpise’s image. |

| 5 | Functions: can add or reduce the quantity of containers,it’s flexible and can be compounded,more economical than brick house. |

| 6 | Other sides: use life can reach 15 years. |

1. How to install the houses in the site?

We can offer you three type of insisting on the installation:

1.1 : We can offer you the manual include the photos and drawings, or some videos for help you on the installation. And you will organize the local people to install it. 93% of our clients finished their houses in this way.

1.2: We can send our people to your site to guide your people to install. Or send team people (3-5 people) to your site to install for you. This way is most easy way, but you need to pay their round-way tickets, local food, accommodation, transportation, communication and salary, and also their security on the site. Almost 5% of our clients choose this way. And in the normal we will require the order should be more than 100000USD.

1.3: You can send your people (engineers or the technician) to our company to study the installation details. 2% of our clients choose this way for their orders.

2. The advantage of the prefab house.

2.1 : Recycle using: you can assemble it in the site A, then disassemble and install again in the site B, then site C. In such way, there is no industrial rubbish after you finish the jobs in the site.

2.2 : Low cost. The steel structure is much lower on the cost then the tradition building.

2.3 : Quickly installation. In the normal, 6 skilled persons team can install 150 sq.m house every day.

2.4: safety: the prefab house can resistance 7 grade earthquake, and 100km/H wind.

3. The mainly use of the prefab house:

In the normal it’s mainly used as temporary building in the site, such as temporary office, labor accommodation, etc. And in the recent years, the prefab house is largely use in the resettlement housing in some disaster area. In 2008, it played a major role on the resettling the victims after the terrible earthquake on 12th, May, 2008.

4. How to maintain your prefab house?

4.1: First of all, when the prefab house is installed, it’s better not to make any other changes, like an expansion, adding partitions or cutting down the walls, or removing screws, and so on.

4.2 : Made the re-paint every 1-2 years after you install it. Such way can increase its service life and keep beautiful.

4.3 : Finally, do not tie the wire to the prefab house, which will lead to the prefab house uneven force and easily cause electric shock accident.

5. How to prepare the foundation for the K style prefab house?

In the normal we will offer you the foundation drawing to prepare the foundation. In the normal the K style house is the strip foundation.

6. How many flooring can the K style prefab house build?

In the normal we will suggest you to do the K style prefab house in 1 floor or 2 floors. And the highest one is 3 floors if you need. And will suggest you not build the house more than 3 floors by K style house. If you want to build the house more than 3 floors you better choose the design of T house design supported by the H shape steel

By the way, if you want to layout the toilet room in the K style prefab house, you’d better made it in the ground floor for the water proofing.

7. The materials option for the thermal insulation:

We have 3 materials for your option:

They are: EPS sandwich panel, glass wool sandwich panel, rock wool sandwich panel, PU (polyurethane) sandwich panel. You can get the details in the description of the sandwich panels.

Product detail pictures:

Related Product Guide:

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Factory best selling Cheap Prefab Cabins - China Supply Sale Low Cost Prices Portable Live Homes Prefabricated Houses – Vanhe , The product will supply to all over the world, such as: Senegal, Lebanon, Angola, We're introduced as a one of the growing manufacture supplier and export of our merchandise. Now we have a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

How to Buy a VHCON Prefab House?

Step 1: Initial Enquiry or Display Hall Visit

Start by contacting the VHCON sales team for a no-obligation chat about your project. We’ll walk you through the options, answer any questions, and explain what’s involved with owning a VHCON Modular House.

You can also book a private tour at our Display Hall to view our houses in person.

Whether you’re still planning or ready to move ahead, this first step is all about giving you clarity, confidence, and expert advice from the start.

Step 2: Site Suitability & Pre-Approval Check

Once you’re ready to proceed, we’ll connect you with our trusted Building Certifier and Structural Engineer for a preliminary assessment. Alternatively you can provide your own preliminary assessment from a town planner or building certifier to assess eligibility.

You will need to provide your own site plan to conduct a preliminary assessment. This preliminary assessment helps identify any potential planning restrictions, zoning issues, or site challenges early on — such as setbacks, overlays, wind speed, and climate zone.

This step ensures you have confidence that your project is likely to meet council and building code requirements before moving further into the approvals process.

Step 3: Contract Signing & Initial Deposit

Once your site has been deemed suitable and you’re ready to move forward, we’ll prepare your Build Contract.

This contract will outline:

- The scope of works and what’s included in your Expander Home package

- Customisations (if any) and your selected finishes

- Estimated timeframes for manufacturing, delivery, and installation

- Payment terms, including deposit and progress payments

To secure your place in our production schedule, a non-refundable initial deposit is required upon signing. This deposit confirms your commitment and allows us to begin the next steps — including final plans, engineering, and scheduling your batch build.

Note: We’ll ensure you have ample time to review and understand all contract details, and we’re here to answer any questions before you sign.

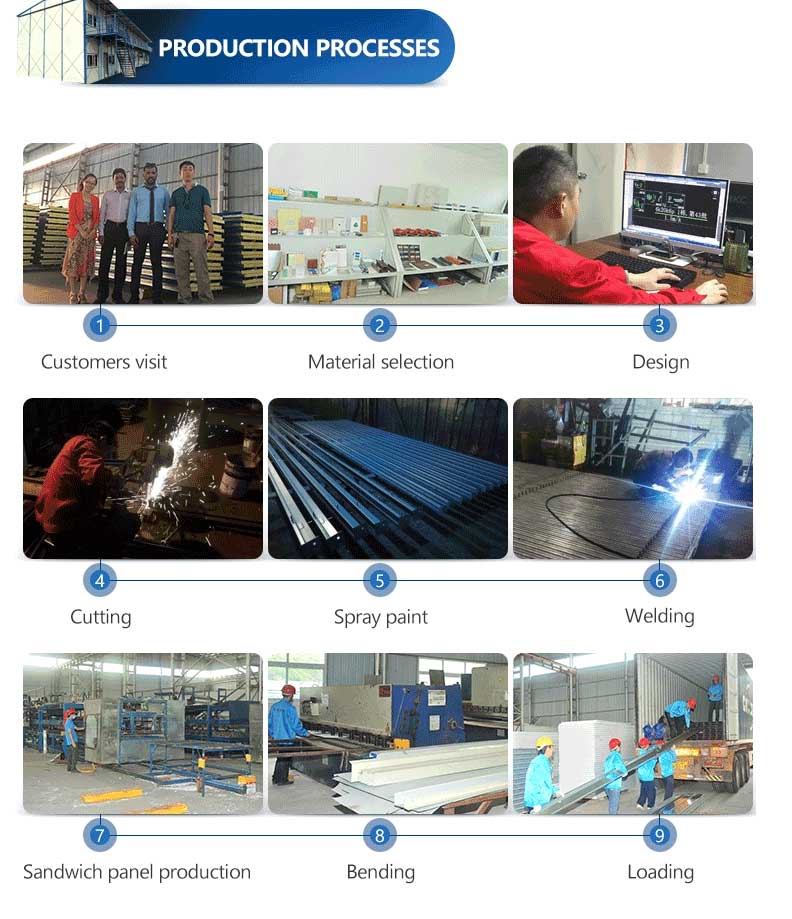

Step 4: Factory Construction

Once your contract is finalised, your home enters our scheduled production process. Built in controlled factory conditions by our trusted manufacturing partners, this approach ensures consistent quality, weather protection, and reliable delivery timelines.

The Express Portables design team oversees all aspects of compliance, workmanship, and detail throughout the build. Construction typically takes 9–11 weeks to complete.

Step 5: Shipping, Transport & Delivery

Once factory construction is complete, your home is carefully prepared for shipment. International shipping from our manufacturing facility typically takes 4–5 weeks.

Transport to your site is scheduled in coordination with you or your site builder. Your builder is responsible for unloading the building onto the prepared footings and beginning the installation process.

After installation, the customer is required to arrange the final Occupancy Certificate, with guidance and support provided by our Building Certifier to ensure a smooth approval process.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.