Factory Cheap Tiny Modular Homes - Storey Prefabricated Living Home Container House for Office – Vanhe

Factory Cheap Tiny Modular Homes - Storey Prefabricated Living Home Container House for Office – Vanhe Detail:

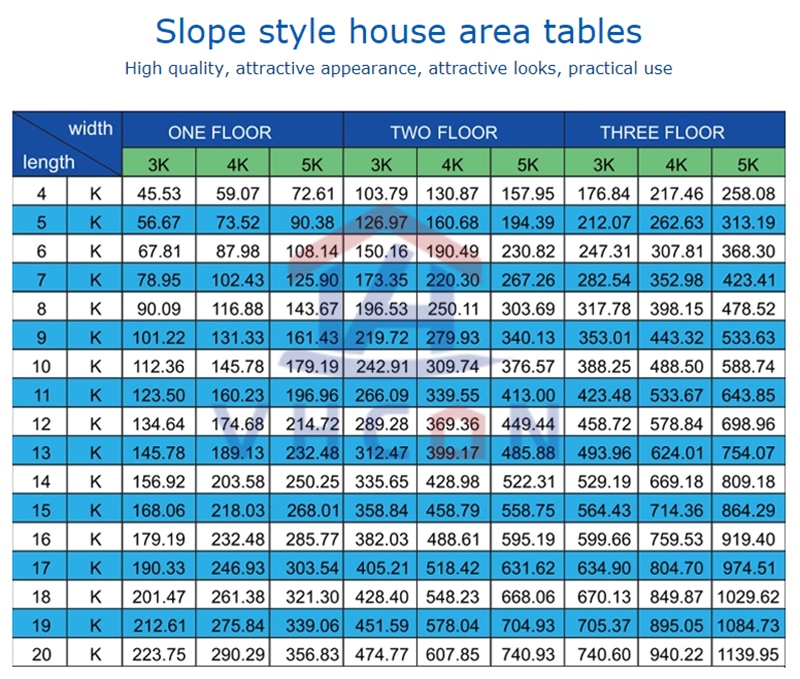

1. General technical description for standard prefabricated house

Technical Parameter:

Technical Parameter of standard prefabricated house:

(1). Wind resistance: Grade 11(wind speed≤ 120km/h)

(2). Earthquake resistance: Grade 7

(3). Live load capacity of roofing: 0.6kn/m2

(4). External and internal wall heat transmission coefficient: 0.35Kcal/m2hc

(5). Second Floor Load Capacity: 150 kg/m2

(6). Live load of corridor is 2.0kn/ m2

(7). Wall permitted loading: 0.6KN/ m2

(8). Ceiling Permitted live loading: 0.5 KN/m2

(9). Wall Coefficient of thermal conductivity: K=0.442W/m2k

(10). Ceiling Coefficient of thermal conductivity: K=0.55W/ m2K

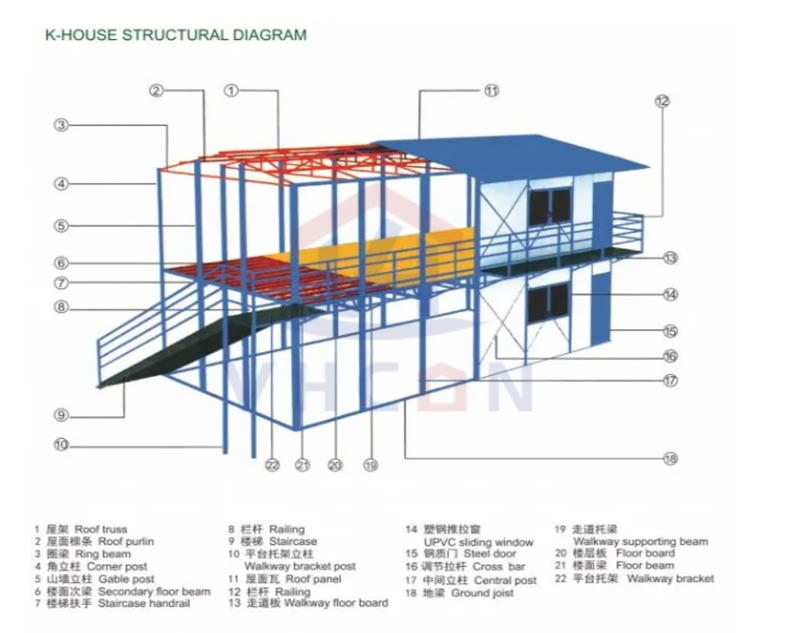

Steel framework

Main column: Fabricated by 80*80 or 100*100 or 120*120 or 150*150 Square Tube, Q235 Steel Surface working: Alkyd painting, two primary and two surface.

Main triangle Beam: Fabricated by C80, C100, C120, C140 Section steel, Q235 Steel, Surface working: Alkyd painting, two primary and two surface.

Wall and roof purlin: C80, C100, C120, C140 Section steel, Q235 Steel,

Surface working: Galvanized

Floor

Ground floor will be the concrete foundation with Ceramic tiles or PVC floor leather.

First floor: 18mm plywood with 2.0mm PVC floor leather for living rooms floor

Ceiling

6mm Gypsum board for dry room

12mm PVC ceiling for wet room

Walls

Insulated Steel Sandwich Panel wall

Panel width: 950mm;

Thickness: 50-1200mm.

Powder coated Color steel on both sides: 0.4mm/0.5mm/0.6mm

Insulation: Polystyrene, Rockwool or Polyurethane

Density of Rockwool: 120Kg/m3

Density of Polystyrene: 12Kg/m3, 16KG/M3 20KG/M3

Density of Polyurethane: 40Kg/m3

Door

External door: Insulated with opening dimension 950*2100mm, furnished with lock, with 3 keys.

Inner door: Insulated steel door.

Windows

Window material: PVC window with fly screen, 4mm glass.

Electrical fittings option

Electrical wire, 2.5mm2 for lighting system, and 4mm2 for AC units.

16A five hole universal socket.

Double tube fluorescent lamp, 220V, 50-60Hz

Single Switch, Honyar brand, with junction box

Electrical distribution box, box+breakers+earth leakage protective device

Optional Water system fittings

(1). Water drain pipe, PPR pipe, dim 16-20mm, connection fittings are made of copper, life span over 10 years.

Exhaust fan or air exchange hole, size 250mm*250mm made of steel or PVC

(2). Sanitary ware:

Western Close tool: Ceramic, with pipes and installation fittings

Urinal: Ceramic, with pipes and installation fittings

Wash basin: Ceramic, with post, faucet, pipes and installation fittings

Shower head, Shower base, Water mixture

Temporary building Characteristics:

(1). Environment protective, no garbage caused

(2). Doors, windows and interior partitions can be flexibly fixed

(3). Beautiful appearance, different colors for the wall and roof.

(4). Cost saving and transportation convenient

(5). Anti-rust and normally more than 15 years using life

(6). Safe and stable, can stand 8 grade earthquake.

2. Our Services:

(1). Professional design and engineering team: Full solution for site camp design. We could make the design for whole camp as per your requirement.

(2). Procurement and Manufacture for all material for prefabricated building. We have a professional procurement team to make sure all the materials are with good quality. And our factory operation under ISO/CE/SGS standard, to make sure the fabrication works with high technology.

(3). Site management & Installation supervision, We could send our engineers to help for the installation supervision, you just need to prepare a team which know normal construction works will be OK.

| Material List For Prefabricated House | |

| Main Steel Frame | |

| Steel column | Fabricated by Q235 or Q345 Steel, 80*80 or 100*100 or 120*120 or 150*150 Square Tube, alkyd paiting, two primary painting, two finish painting. |

| Triangular Steel structure roof | Fabricated by Q235 or Q345 Steel, C80, C100, C120, C140 Section steel, alkyd paiting, two primary painting, two finish painting. |

| Roof Purlin | Fabricated by Q235 Steel, C80, C100, C120, C140 Section steel, alkyd paiting, two primary painting, two finish painting. |

| Ordinary bolt | 4.8S, Galvanized |

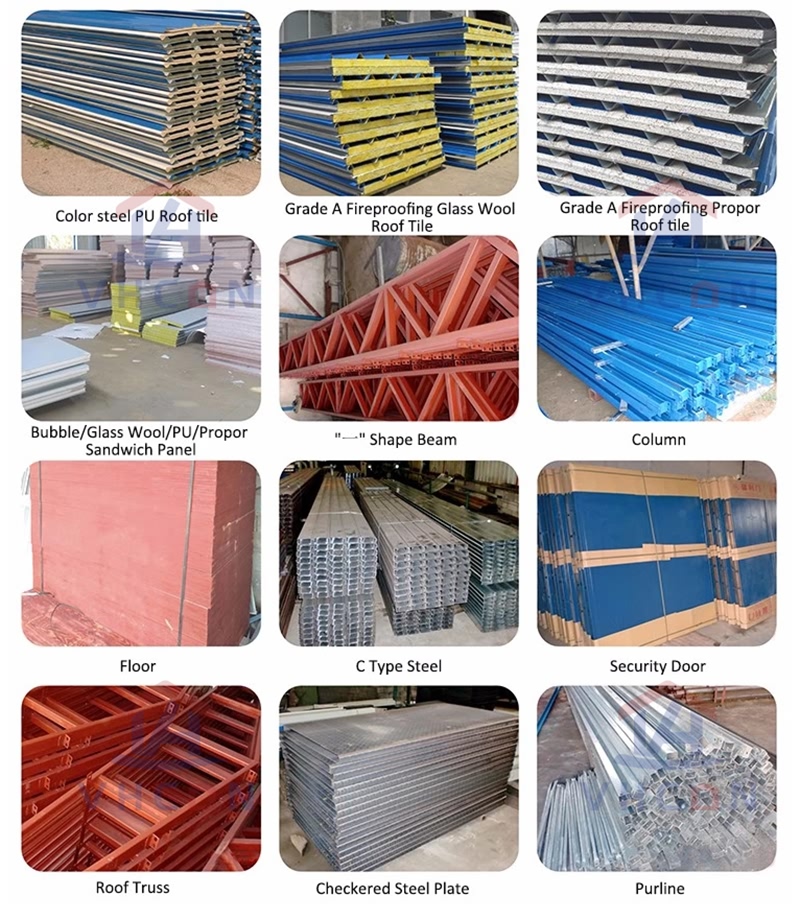

| Roof and Wall | |

| Roof Panel | A: Insulated Steel Sandwich Panel wall (1) Panel width: 950mm; (2) Thickness: 50-1200mm. (3) Powder coated Color steel on both sides: 0.4mm/0.5mm/0.6mm B: Insulation: Polystyrene, Rockwool, Fiber Glass or Polyurethane (1) Density of Rockwool: 120Kg/m3 (2) Density of Polystyrene: 12Kg/m3, 16KG/M3 20KG/M3 (3) Density of Polyurethane: 40Kg/m3 (4) Density of Fiber Glass:40Kg/m3, 60Kg/m3 |

| Wall Panel | A: Insulated Steel Sandwich Panel wall (1) Panel width: 950mm; (2) Thickness: 50-1200mm. (3) Powder coated Color steel on both sides: 0.4mm/0.5mm/0.6mm B: Insulation: Polystyrene, Rockwool, Fiber Glass or Polyurethane (1) Density of Rockwool: 120Kg/m3 (2) Density of Polystyrene: 12Kg/m3, 16KG/M3 20KG/M3 (3) Density of Polyurethane: 40Kg/m3 (4) Density of Fiber Glass:40Kg/m3, 60Kg/m3 |

| Edge Cover | 0.4mm galvanized color steel , angle Alu. |

| Fasteners & Accessoreis | Nailsglue ect |

| Ceiling&Flooring | |

| Ceiling | 6mm gypsum board,with steel keel |

| Plywood | 18mm film faced plywood |

| Floor feather | 1.5mm PVC floor leather |

| Door and window | |

| Door | (1) External door: Single open door. Insulated with opening dimension 950*2100mm, furnished with lock with 3keys. (2) Inner door: Single open door. Insulated steel door. |

| Window | 4mm glass PVC window witn flying screem |

| Electrical System | |

| Electric Cable | (1) Three diferent color. (2) Lighting: 2.5m m2. (3) Air condition: 4.0mm2. (4) BV cable, solid core. |

| PVC Wire Channel | PVC wire channel |

| Lights | Double tube fluorescent lamp, 220V,50-60HZ |

| Switches | Single Switch, with junction box |

| Socket | 16A five hole univesal socket. |

| Power Distribution Cabinet | Box+breakers+earth leakage protective device |

| Water&Plumbing system(choose) | |

| Water drain pipe | (1) PPR pipe, dim 16-20mm, connection fittings are made of copper, life span over 10 years. (2) Exhaust fan or air exchange hole, size 250mm*250mm made of steel or PVC |

| Sanitary ware | (1) Western Close tool: ceramic, with pipes and installation fittings (2) Urinal: ceramic, with pipes and installation fittings (3) Wash basin: ceramic, with post, faucet, pipes and installation fittings (4) Shower head, Shower base, Water mixture |

| Plumbing System and Rain Water Drainage System as per building design | |

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Factory Cheap Tiny Modular Homes - Storey Prefabricated Living Home Container House for Office – Vanhe , The product will supply to all over the world, such as: Lesotho, Lithuania, Nigeria, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our solutions, you should do not hesitate to contact us for further information.

How to Buy a VHCON Prefab House?

Step 1: Initial Enquiry or Display Hall Visit

Start by contacting the VHCON sales team for a no-obligation chat about your project. We’ll walk you through the options, answer any questions, and explain what’s involved with owning a VHCON Modular House.

You can also book a private tour at our Display Hall to view our houses in person.

Whether you’re still planning or ready to move ahead, this first step is all about giving you clarity, confidence, and expert advice from the start.

Step 2: Site Suitability & Pre-Approval Check

Once you’re ready to proceed, we’ll connect you with our trusted Building Certifier and Structural Engineer for a preliminary assessment. Alternatively you can provide your own preliminary assessment from a town planner or building certifier to assess eligibility.

You will need to provide your own site plan to conduct a preliminary assessment. This preliminary assessment helps identify any potential planning restrictions, zoning issues, or site challenges early on — such as setbacks, overlays, wind speed, and climate zone.

This step ensures you have confidence that your project is likely to meet council and building code requirements before moving further into the approvals process.

Step 3: Contract Signing & Initial Deposit

Once your site has been deemed suitable and you’re ready to move forward, we’ll prepare your Build Contract.

This contract will outline:

- The scope of works and what’s included in your Expander Home package

- Customisations (if any) and your selected finishes

- Estimated timeframes for manufacturing, delivery, and installation

- Payment terms, including deposit and progress payments

To secure your place in our production schedule, a non-refundable initial deposit is required upon signing. This deposit confirms your commitment and allows us to begin the next steps — including final plans, engineering, and scheduling your batch build.

Note: We’ll ensure you have ample time to review and understand all contract details, and we’re here to answer any questions before you sign.

Step 4: Factory Construction

Once your contract is finalised, your home enters our scheduled production process. Built in controlled factory conditions by our trusted manufacturing partners, this approach ensures consistent quality, weather protection, and reliable delivery timelines.

The Express Portables design team oversees all aspects of compliance, workmanship, and detail throughout the build. Construction typically takes 9–11 weeks to complete.

Step 5: Shipping, Transport & Delivery

Once factory construction is complete, your home is carefully prepared for shipment. International shipping from our manufacturing facility typically takes 4–5 weeks.

Transport to your site is scheduled in coordination with you or your site builder. Your builder is responsible for unloading the building onto the prepared footings and beginning the installation process.

After installation, the customer is required to arrange the final Occupancy Certificate, with guidance and support provided by our Building Certifier to ensure a smooth approval process.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!