factory low price Small Chicken Coop – China best supplier steel frame layer egg chicken cage poultry farm construction house design for sale in Kenya – Vanhe

factory low price Small Chicken Coop – China best supplier steel frame layer egg chicken cage poultry farm construction house design for sale in Kenya – Vanhe Detail:

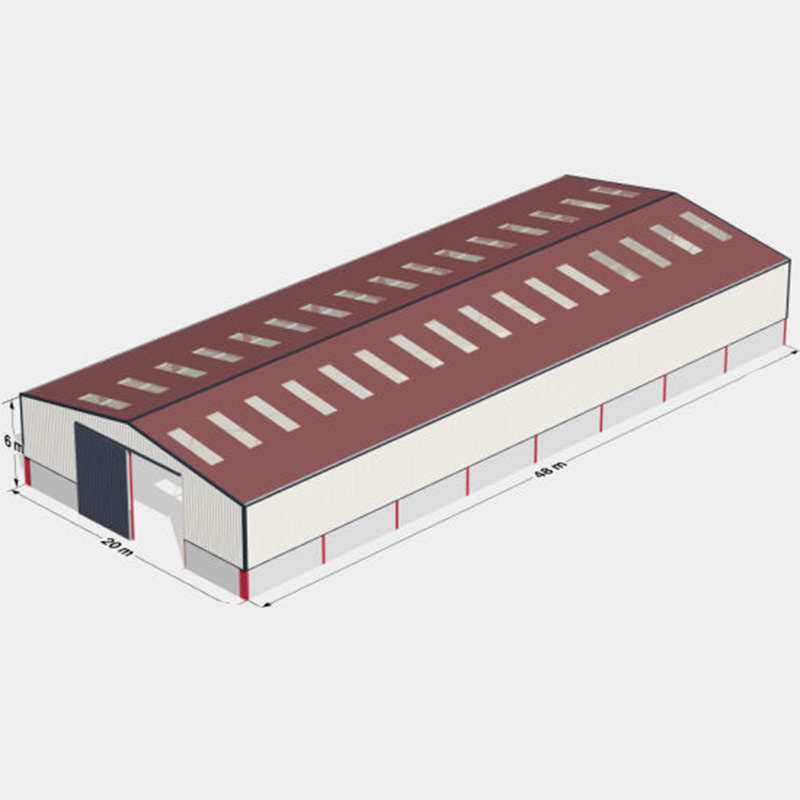

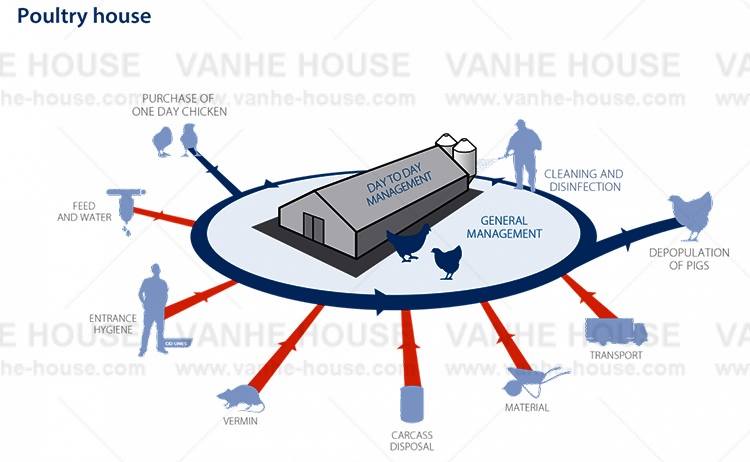

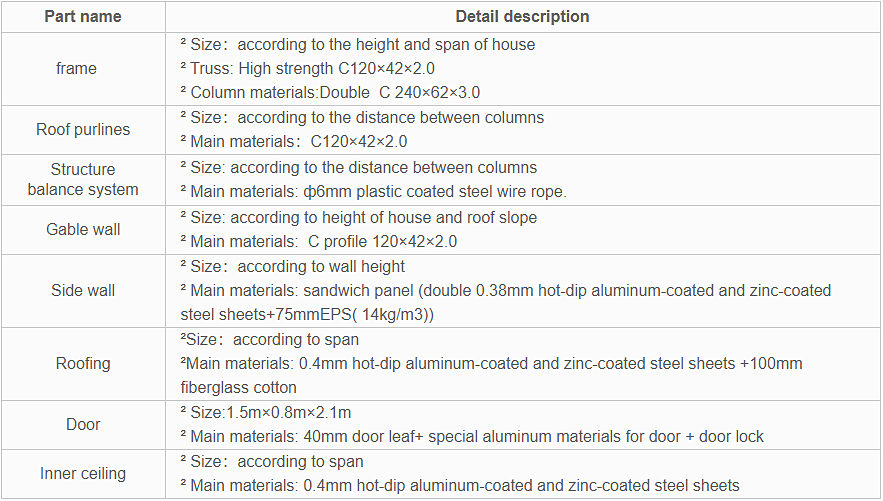

1. Poultry house

Vanhe Modular House Co., Ltd is a professional manufacturer of steel structure in China. Design, supply & install steel structure buildings(steel structure workshop, steel structure warehouse buildings, steel structure hangar), with ISO9001, SGS and CE certification, 20+year experiences, 90+ countries exported: Ethiopia, Tanzania, Nigeria, South Africa, Algeria, Dubai, Saudi Arabia, Thailand, Australia, France, Germany etc. Around the world.

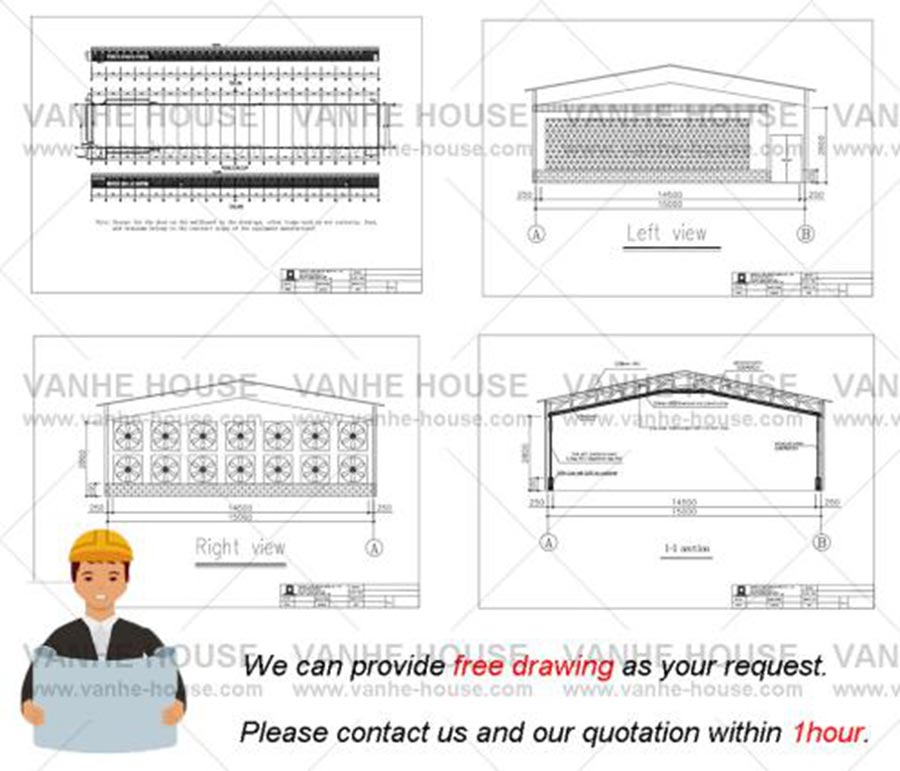

The structure of customized poultry farm are flexible because different customers need different style. We help the customer design the structure to meet the individual requirements. We provide free design for you. Of course, we can follow your drawings to arrange. Our fireproof prefabricated wall battery prefab light steel hen house has many features. Low cost small prices, standardization, modular combination design, factory production, removable mobile, reusable, easy to stock restructuring, safe, environmental protection, beautiful and efficient light steel system integration house.

1.Main feed Ddelivery line

(1. )Main feed delivery system is a complete set of automatic feeding system, included a material conveying pipe, silo, auger, drive motor and a feed level sensor.

(2) Main Feed line is mainly used to deliver feed from silo to the hopper in the poultry house. There is one feed sensor at the end of main feed line, which can control the drive motor on and off to realize automatically feeding.

Different specifications of silos are alternative to choose according to the daily consumption.

2. Automatic pan feeding line system

There is a sensor at each feeding line which controls motor on and off to achieve automatically feed delivery.

The motor will start working and deliver feed when the feed pan (with sensor)

lacks feed and will stop working when the feed pan (with sensor) is full of feed.

3. Automatic nipple drinking line system

This system can provide fresh and clean water for poultry which is crucial for the growth of Poultry.

The drinkers can be triggered from 360 degree which helps young birds start well and makes drinking easier.

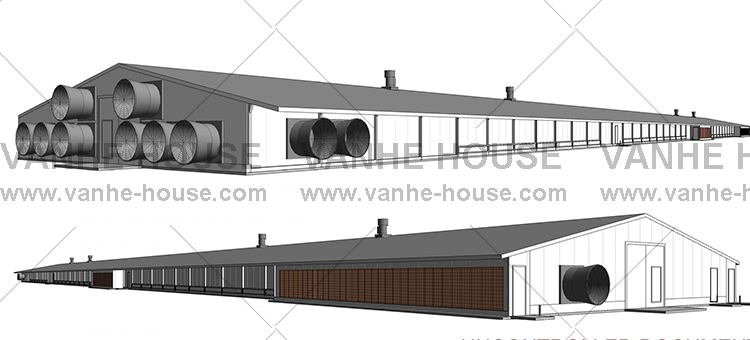

4.Cooling pad system

Evaporative cooling pad system works in the condition of negative pressure, the cooling pad is installed on one side of the wall, fan installed other side. When air flow through cooling pads, the water evaporation absorbs a lot amount of heat.

The height of cooling pad is 1.5-2.2m, the area of cooling pad in chicken house is about 6-8 times than the fans.

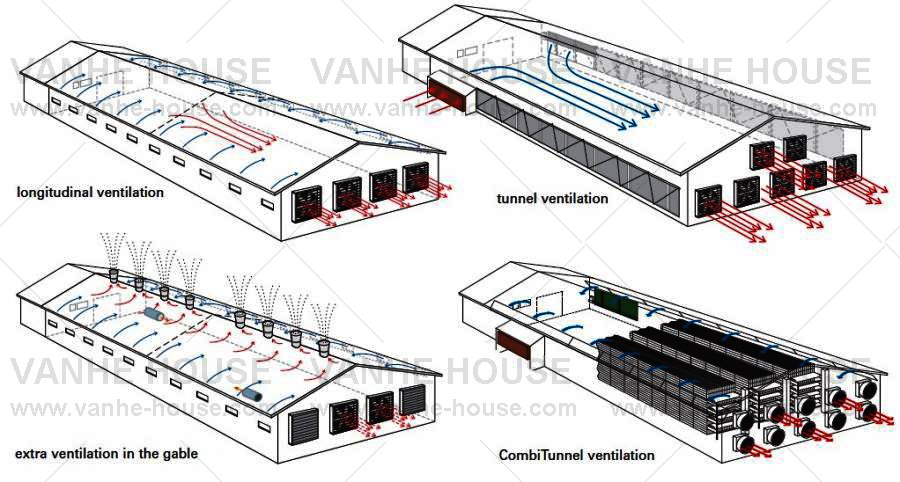

5. Ventilating system

The main parts of ventilation system is the big fan and small fan. They are controlled by the control system. The NO. of the fans to run was decided by the temperature of the poultry house.

About 200m2 need 1 big fan and 15-20m need a small fan, this is the standard to design the quantity of fans in chicken house

1.Advantage

Advantages of Steel Structure:

1.Make accessories & surface treatment including HDG ourselves

-Easy to control quality and cost;

2.Big & Complete Supply Chain

-We buy from famous & big manufacturers directly, not their agents;

3. Strict QC polity

-Our products must pass Size tests, Assembly tests and Mechanical property

tests before packed;

4.Customized size products

- as per customer’ S requirement;

5.Rich Experienced Design, Production and Service Team

6.Convenient transport and environment for exporting

-Located in Dongguan, which is a industry city, a seaport city and a tourist city;

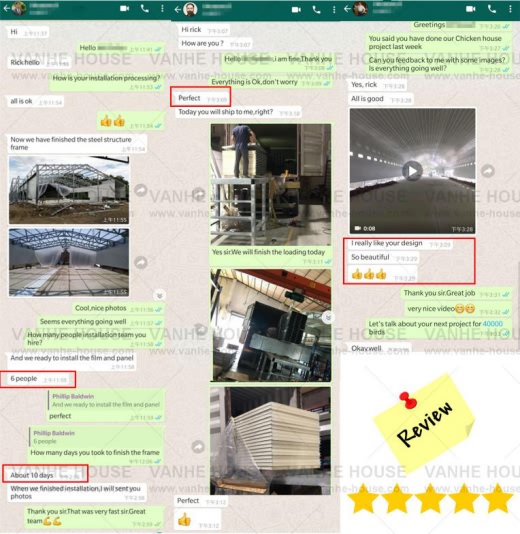

2.Overseas Project & Review

(Over than 2000+projects)

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for factory low price Small Chicken Coop – China best supplier steel frame layer egg chicken cage poultry farm construction house design for sale in Kenya – Vanhe , The product will supply to all over the world, such as: Detroit, Bulgaria, Turkey, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

How to Buy a VHCON Prefab House?

Step 1: Initial Enquiry or Display Hall Visit

Start by contacting the VHCON sales team for a no-obligation chat about your project. We’ll walk you through the options, answer any questions, and explain what’s involved with owning a VHCON Modular House.

You can also book a private tour at our Display Hall to view our houses in person.

Whether you’re still planning or ready to move ahead, this first step is all about giving you clarity, confidence, and expert advice from the start.

Step 2: Site Suitability & Pre-Approval Check

Once you’re ready to proceed, we’ll connect you with our trusted Building Certifier and Structural Engineer for a preliminary assessment. Alternatively you can provide your own preliminary assessment from a town planner or building certifier to assess eligibility.

You will need to provide your own site plan to conduct a preliminary assessment. This preliminary assessment helps identify any potential planning restrictions, zoning issues, or site challenges early on — such as setbacks, overlays, wind speed, and climate zone.

This step ensures you have confidence that your project is likely to meet council and building code requirements before moving further into the approvals process.

Step 3: Contract Signing & Initial Deposit

Once your site has been deemed suitable and you’re ready to move forward, we’ll prepare your Build Contract.

This contract will outline:

- The scope of works and what’s included in your Expander Home package

- Customisations (if any) and your selected finishes

- Estimated timeframes for manufacturing, delivery, and installation

- Payment terms, including deposit and progress payments

To secure your place in our production schedule, a non-refundable initial deposit is required upon signing. This deposit confirms your commitment and allows us to begin the next steps — including final plans, engineering, and scheduling your batch build.

Note: We’ll ensure you have ample time to review and understand all contract details, and we’re here to answer any questions before you sign.

Step 4: Factory Construction

Once your contract is finalised, your home enters our scheduled production process. Built in controlled factory conditions by our trusted manufacturing partners, this approach ensures consistent quality, weather protection, and reliable delivery timelines.

The Express Portables design team oversees all aspects of compliance, workmanship, and detail throughout the build. Construction typically takes 9–11 weeks to complete.

Step 5: Shipping, Transport & Delivery

Once factory construction is complete, your home is carefully prepared for shipment. International shipping from our manufacturing facility typically takes 4–5 weeks.

Transport to your site is scheduled in coordination with you or your site builder. Your builder is responsible for unloading the building onto the prepared footings and beginning the installation process.

After installation, the customer is required to arrange the final Occupancy Certificate, with guidance and support provided by our Building Certifier to ensure a smooth approval process.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!