New Arrival China Portable Toilet Manufacturer - Cheap plastic public mobile squat toilet portable – Vanhe

New Arrival China Portable Toilet Manufacturer - Cheap plastic public mobile squat toilet portable – Vanhe Detail:

1.Mobile Toilet

HDPE Toilet

●Portable Toilet also called HDPE Toilet, Plastic Site Toilet, Movable Site Toilet, Site Chemical Toilets, Modular Portable Toilets, Red Economic Toilets and Site Toilets, refer to toilet stalls that are made from HDPE panels & installed with ventilation, door, electrics, plumbing, sanitary,sometimes also included clean water tanks & waste tanks.

●Such portable toilets are commonly used in construction sites, oil sites, mining sites as workers’ toilets, site showers, also used for solider camps, government projects & school projects as temporary site toilets & bathrooms.

1.Movable, thus avoiding the waste of resources caused by house demolition.

2.The processing method is various, and the appropriate processing method can be adopted according to the limitation of the use environment.

3.The floor space is small. Compared with the traditional toilets, the mobile toilets have greatly saved the land area, which just caters to the current situation of land shortage!

4.Beautiful and generous, on the basis of ensuring practicality, pay attention to the importance of beauty, and become a scenic spot of tourist attractions and park communities!

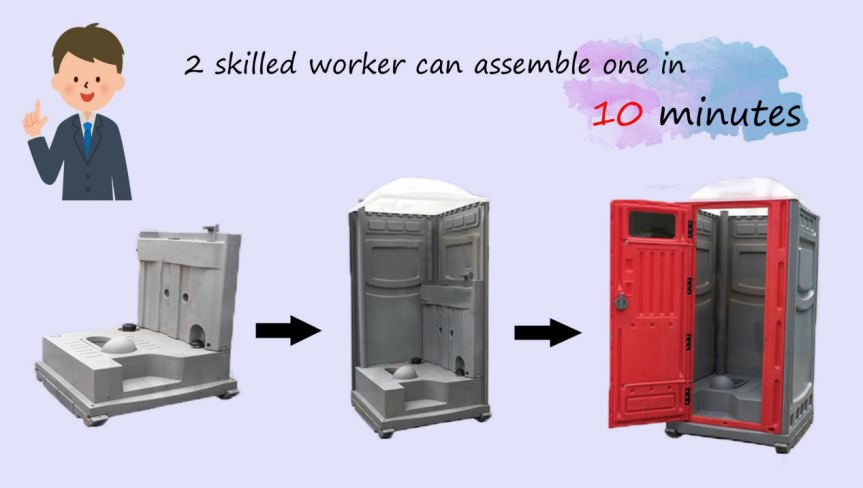

5. Significantly save manpower, material and financial resources in the construction. The construction of traditional toilets usually needs to be selected, purchased, constructed, completed, put into use, etc.

1. Portable Toilets flushing has a spring valve, can isolate the smell into the toilet. The roof is made of HDPE with two layers of thickening and natural lighting to ensure that the interior of the toilet is bright.

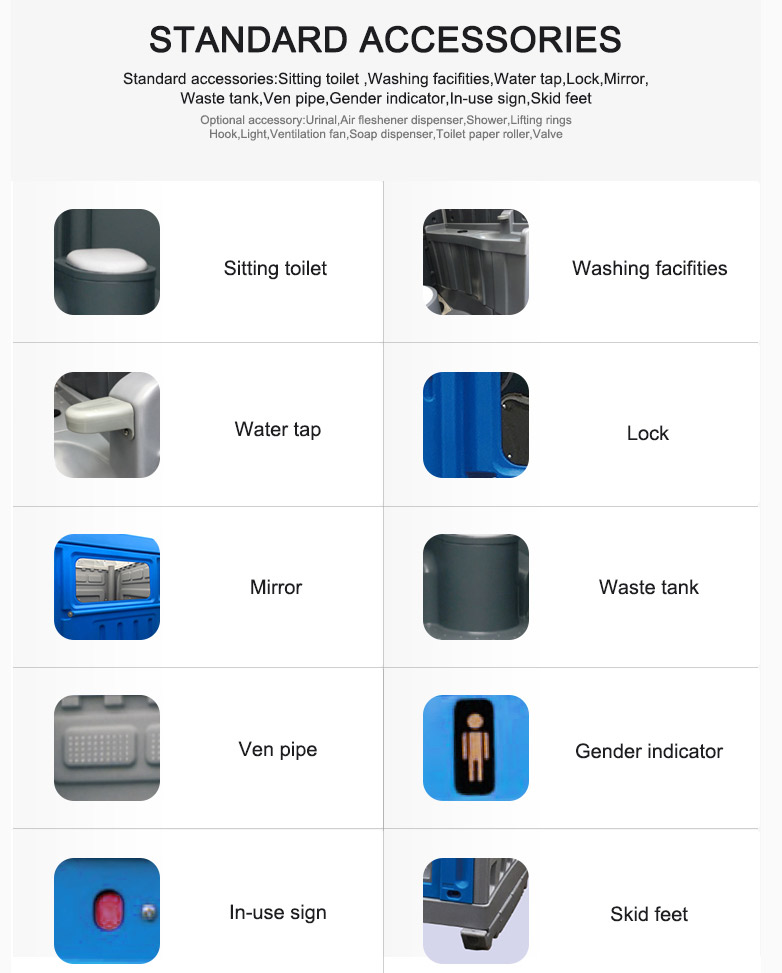

2.The color is diverse, the conventional red, yellow and blue. User-friendly configuration, such as coat hooks, vanity mirrors, etc.

3.Movable Toilets are gender signs, automatic door closer and padlocks, which can be locked when not in use.

4.HDPE Mobile Portable Toilet have nice appearance, a wide range of use, such as outdoor wedding scenes, marathon events, convention centers, commercial areas, tourist attractions, subway stations, construction sites.

2.Details

4.Packing

1. All products are designed to be shipped disassembly.

2. Packing method is bubble paper with plastic film.

3. One 20ft container can fit 30 disassembled units; one 40ft container can fit 60 units; one 40HQ container can fit 70 units.

Product detail pictures:

Related Product Guide:

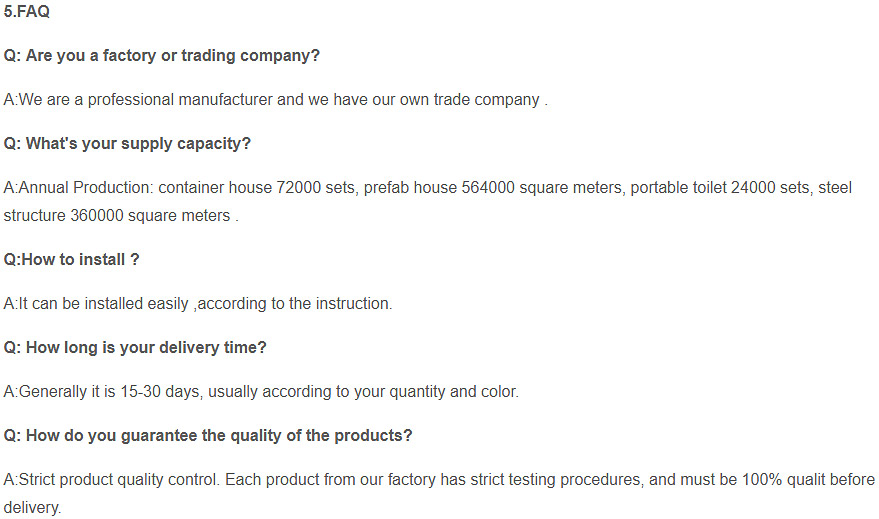

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for New Arrival China Portable Toilet Manufacturer - Cheap plastic public mobile squat toilet portable – Vanhe , The product will supply to all over the world, such as: Bandung, Uruguay, Jeddah, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

How to Buy a VHCON Prefab House?

Step 1: Initial Enquiry or Display Hall Visit

Start by contacting the VHCON sales team for a no-obligation chat about your project. We’ll walk you through the options, answer any questions, and explain what’s involved with owning a VHCON Modular House.

You can also book a private tour at our Display Hall to view our houses in person.

Whether you’re still planning or ready to move ahead, this first step is all about giving you clarity, confidence, and expert advice from the start.

Step 2: Site Suitability & Pre-Approval Check

Once you’re ready to proceed, we’ll connect you with our trusted Building Certifier and Structural Engineer for a preliminary assessment. Alternatively you can provide your own preliminary assessment from a town planner or building certifier to assess eligibility.

You will need to provide your own site plan to conduct a preliminary assessment. This preliminary assessment helps identify any potential planning restrictions, zoning issues, or site challenges early on — such as setbacks, overlays, wind speed, and climate zone.

This step ensures you have confidence that your project is likely to meet council and building code requirements before moving further into the approvals process.

Step 3: Contract Signing & Initial Deposit

Once your site has been deemed suitable and you’re ready to move forward, we’ll prepare your Build Contract.

This contract will outline:

- The scope of works and what’s included in your Expander Home package

- Customisations (if any) and your selected finishes

- Estimated timeframes for manufacturing, delivery, and installation

- Payment terms, including deposit and progress payments

To secure your place in our production schedule, a non-refundable initial deposit is required upon signing. This deposit confirms your commitment and allows us to begin the next steps — including final plans, engineering, and scheduling your batch build.

Note: We’ll ensure you have ample time to review and understand all contract details, and we’re here to answer any questions before you sign.

Step 4: Factory Construction

Once your contract is finalised, your home enters our scheduled production process. Built in controlled factory conditions by our trusted manufacturing partners, this approach ensures consistent quality, weather protection, and reliable delivery timelines.

The Express Portables design team oversees all aspects of compliance, workmanship, and detail throughout the build. Construction typically takes 9–11 weeks to complete.

Step 5: Shipping, Transport & Delivery

Once factory construction is complete, your home is carefully prepared for shipment. International shipping from our manufacturing facility typically takes 4–5 weeks.

Transport to your site is scheduled in coordination with you or your site builder. Your builder is responsible for unloading the building onto the prepared footings and beginning the installation process.

After installation, the customer is required to arrange the final Occupancy Certificate, with guidance and support provided by our Building Certifier to ensure a smooth approval process.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.