Reasonable price Portable Potty - NEW DESIGN Durable Roto Moulding Pe Squat Plastic Mobile Outdoor Plastic Mobile Portable Toilet – Vanhe

Reasonable price Portable Potty - NEW DESIGN Durable Roto Moulding Pe Squat Plastic Mobile Outdoor Plastic Mobile Portable Toilet – Vanhe Detail:

1.Mobile Toilet

HDPE Toilet

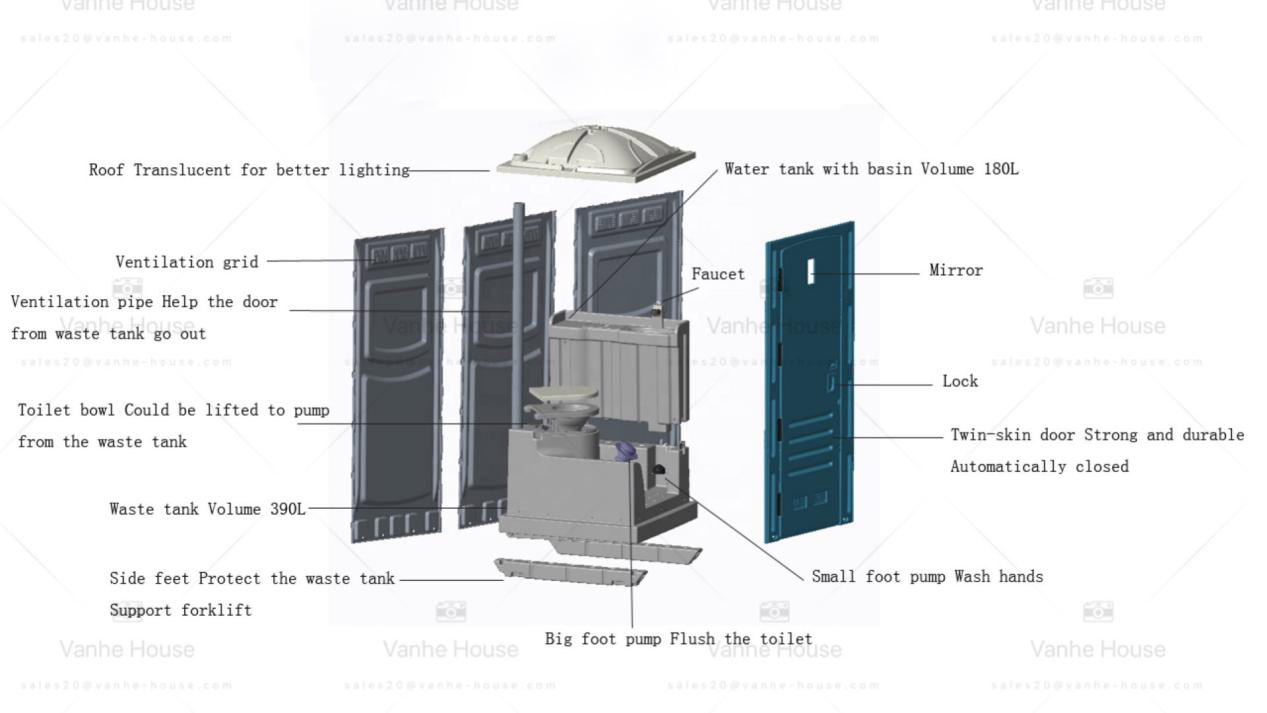

When we do outdoor activities or working, it come physical problem. Where can we find the restroom if we locate mountains, high level, beach or public activities. Therefore, our portable toilet unit is manufactured using virgin HDPE which is high density and anti-ultraviolet (UV) treatment. So, it is durable. Besides, it has a tissue dispenser, translucent roof with air vent. These features it is also equipped with self-closing door with indicator and latch. This exceptional portable toilet has been provided for construction companies, rental business , official and special events etc.

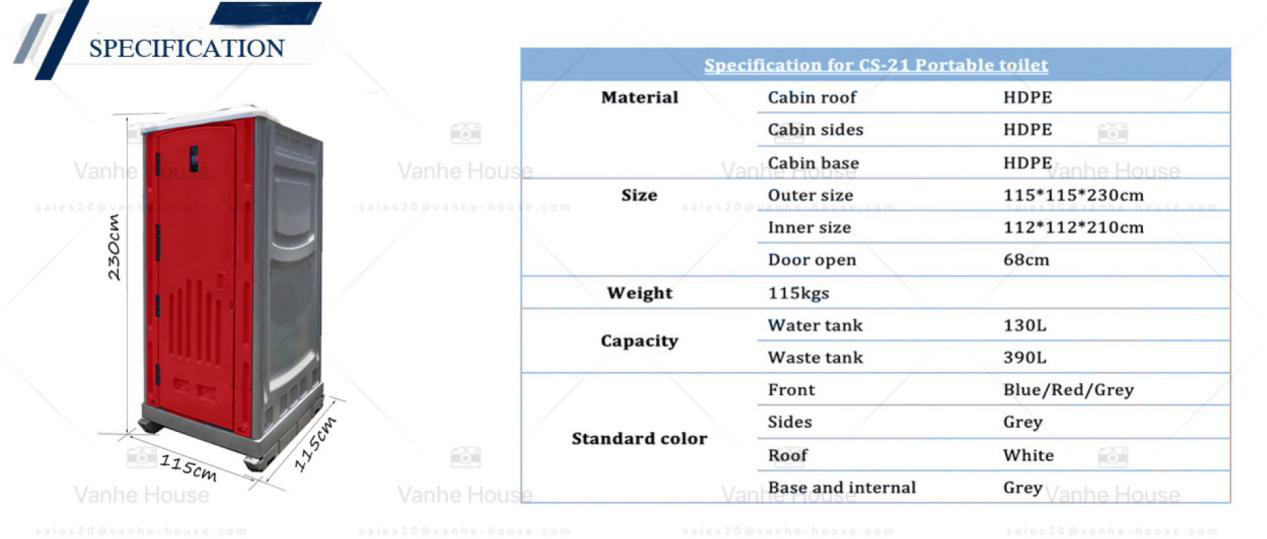

| Material: | HDPE; rolomoding plastic. |

| Size: | 1150mm*1150mm*2300mm |

| Weight: | 115kgs |

| Toilet type: | seated or squat toilet pan |

| Independent Capacity: | 130L |

| Waste holding tank Capacity: | 390L |

| Hand washing facility? | YES |

| Urinal? | As per order |

| Shower? | As per order |

| Transportation: | 22units/20GP; 55 units/40HQ. |

| Accessories: | Toilet bowl; Foot pumps; Washing basin; Water tap; Ventilation pipe; Gender sign; In-use indicator; Skid feet.Optional soap dispenser; Optional toilet paper roller; Optional Valve; and etc. |

What Is HDPE?

HDPE (high-density polyethylene) is a solid plastic material that can be used for a variety of uses. Due to its solid construction, it proves to be highly durable and even resistant to scratches, dents, and impacts. Its homogenous color makes it resistant to graffiti, which is a common scourge with bathroom stalls. HDPE actually has several advantages over other materials that are commonly used with toilet partitions in commercial bathrooms.

Why HDPE Is a Better Pick

One of the major advantages that HDPE has over traditional plastics and laminates is that it has a solid body construction, allowing it to bask in the humidity and moisture without the threat of mold growth. Because it stands up to the elements and mold, it helps keep the air quality in the restroom safe and clean. Other materials would need a costly replacement if the presence of mold is detected.

HDPE is also stronger than the other toilet partition materials. It can take a few hits and still retain its overall aesthetic. During the presence of graffiti, other materials need to be repainted, which results in VOC (volatile organic compounds) emissions, reducing the air quality. Graffiti on HDPE materials can simply be wiped away.

2.Details

3.Advantage

1. Easy to move

2. Unbreakable corner construction

3. Maximum ventilation

4. Easy to clean

5. Low maintenance

6. Luxury interior

5.FAQ

Q: Are you a factory or trading company?

A:We are a professional manufacturer and we have our own trade company .

Q: What’s your supply capacity?

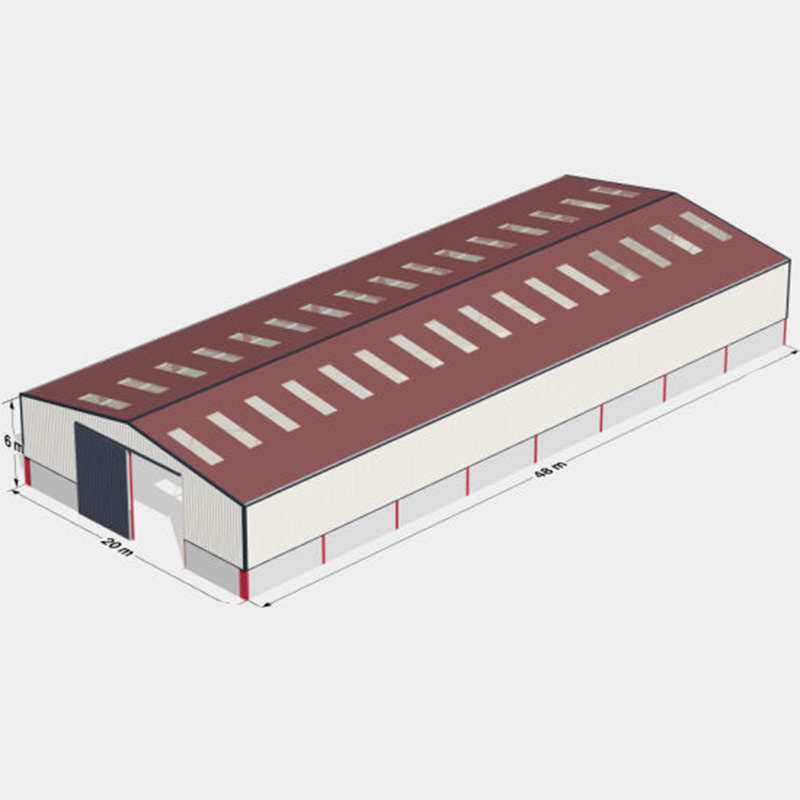

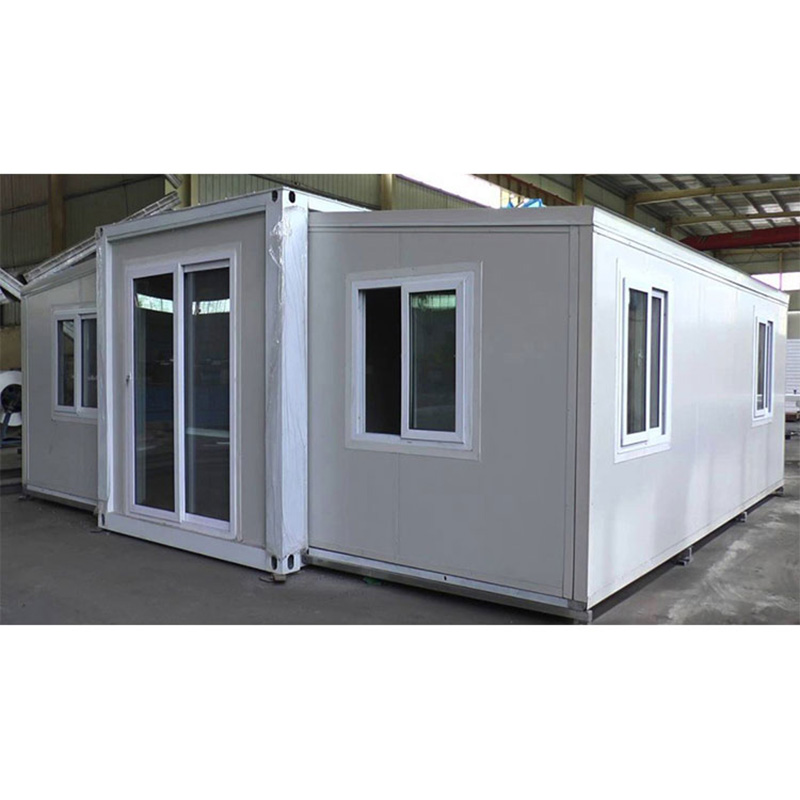

A:Annual Production: container house 72000 sets, prefab house 564000 square meters, portable toilet 24000 sets, steel structure 360000 square meters .

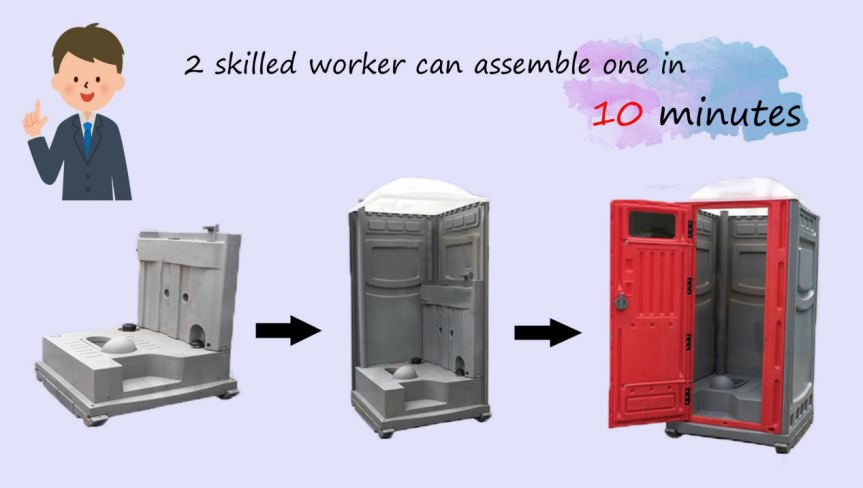

Q:How to install ?

A:It can be installed easily ,according to the instruction.

Q: How long is your delivery time?

A:Generally it is 15-30 days, usually according to your quantity and color.

Q: How do you guarantee the quality of the products?

A:Strict product quality control. Each product from our factory has strict testing procedures, and must be 100% qualit before delivery.

Product detail pictures:

Related Product Guide:

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Reasonable price Portable Potty - NEW DESIGN Durable Roto Moulding Pe Squat Plastic Mobile Outdoor Plastic Mobile Portable Toilet – Vanhe , The product will supply to all over the world, such as: Iran, Istanbul, Argentina, Only for accomplishing the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

How to Buy a VHCON Prefab House?

Step 1: Initial Enquiry or Display Hall Visit

Start by contacting the VHCON sales team for a no-obligation chat about your project. We’ll walk you through the options, answer any questions, and explain what’s involved with owning a VHCON Modular House.

You can also book a private tour at our Display Hall to view our houses in person.

Whether you’re still planning or ready to move ahead, this first step is all about giving you clarity, confidence, and expert advice from the start.

Step 2: Site Suitability & Pre-Approval Check

Once you’re ready to proceed, we’ll connect you with our trusted Building Certifier and Structural Engineer for a preliminary assessment. Alternatively you can provide your own preliminary assessment from a town planner or building certifier to assess eligibility.

You will need to provide your own site plan to conduct a preliminary assessment. This preliminary assessment helps identify any potential planning restrictions, zoning issues, or site challenges early on — such as setbacks, overlays, wind speed, and climate zone.

This step ensures you have confidence that your project is likely to meet council and building code requirements before moving further into the approvals process.

Step 3: Contract Signing & Initial Deposit

Once your site has been deemed suitable and you’re ready to move forward, we’ll prepare your Build Contract.

This contract will outline:

- The scope of works and what’s included in your Expander Home package

- Customisations (if any) and your selected finishes

- Estimated timeframes for manufacturing, delivery, and installation

- Payment terms, including deposit and progress payments

To secure your place in our production schedule, a non-refundable initial deposit is required upon signing. This deposit confirms your commitment and allows us to begin the next steps — including final plans, engineering, and scheduling your batch build.

Note: We’ll ensure you have ample time to review and understand all contract details, and we’re here to answer any questions before you sign.

Step 4: Factory Construction

Once your contract is finalised, your home enters our scheduled production process. Built in controlled factory conditions by our trusted manufacturing partners, this approach ensures consistent quality, weather protection, and reliable delivery timelines.

The Express Portables design team oversees all aspects of compliance, workmanship, and detail throughout the build. Construction typically takes 9–11 weeks to complete.

Step 5: Shipping, Transport & Delivery

Once factory construction is complete, your home is carefully prepared for shipment. International shipping from our manufacturing facility typically takes 4–5 weeks.

Transport to your site is scheduled in coordination with you or your site builder. Your builder is responsible for unloading the building onto the prepared footings and beginning the installation process.

After installation, the customer is required to arrange the final Occupancy Certificate, with guidance and support provided by our Building Certifier to ensure a smooth approval process.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.