Reliable Supplier House Of A Chicken - Hot Sale Large Metal Modern Rain Resistance Steel Structure Chicken Home Poultry House Cow Farm Building – Vanhe

Reliable Supplier House Of A Chicken - Hot Sale Large Metal Modern Rain Resistance Steel Structure Chicken Home Poultry House Cow Farm Building – Vanhe Detail:

1.VANHE Poultry House

Vanhe Modular House Co., Ltd is a professional manufacturer of steel structure in China. Design, supply & install steel structure buildings(steel structure workshop, steel structure warehouse buildings, steel structure hangar), with ISO9001, SGS and CE certification, 20+year experiences, 90+ countries exported: Ethiopia, Tanzania, Nigeria, South Africa, Algeria, Dubai, Saudi Arabia, Thailand, Australia, France, Germany etc. Around the world.

As long as you can have your own thoughts, we will help you to realize it.

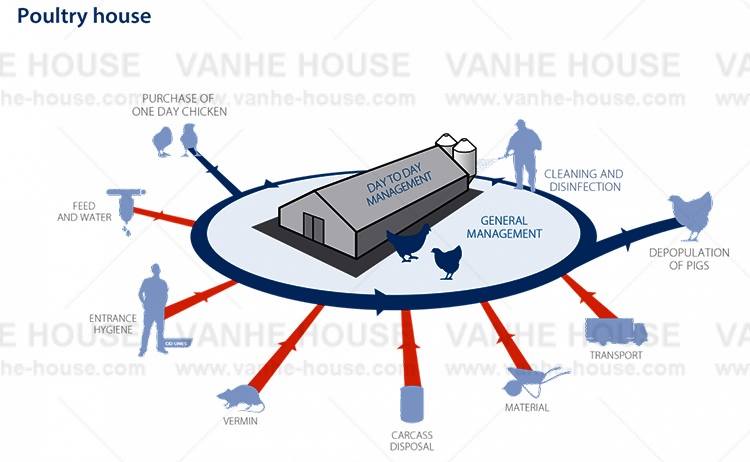

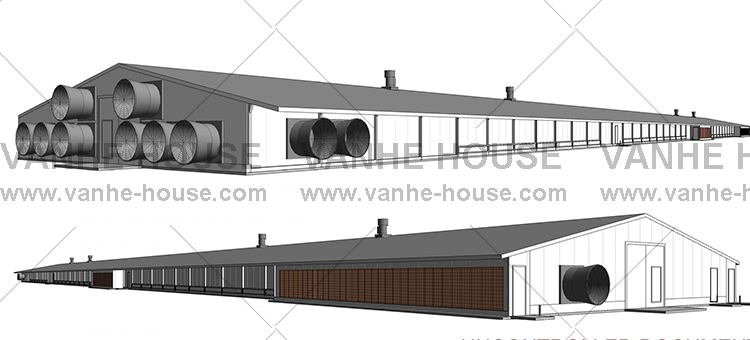

Poultry farm is mainly used for broiler and layer chicken, you can choose free range or cage system with automatic equipment to breed.

We can introduce our partner (the equipments’ supplier )to you,then we work together to provide more workable project for you.

|

Part name |

Detail description |

|

frame |

² Size:according to the height and span of house ² Truss: High strength C120×42×2.0 ² Column materials:Double C 240×62×3.0 |

|

Roof purlines |

² Size:according to the distance between columns ² Main materials:C120×42×2.0 |

|

Structure balance system |

² Size: according to the distance between columns ² Main materials: ф6mm plastic coated steel wire rope. |

|

Gable wall |

² Size: according to height of house and roof slope ² Main materials: C profile 120×42×2.0 |

|

Side wall |

² Size:according to wall height ² Main materials: sandwich panel (double 0.38mm hot-dip aluminum-coated and zinc-coated steel sheets+75mmEPS( 14kg/m3)) |

|

Roofing |

²Size:according to span ²Main materials: 0.4mm hot-dip aluminum-coated and zinc-coated steel sheets +100mm fiberglass cotton |

|

Door |

² Size:1.5m×0.8m×2.1m ² Main materials: 40mm door leaf+ special aluminum materials for door + door lock |

|

Inner ceiling |

² Size:according to span ² Main materials: 0.4mm hot-dip aluminum-coated and zinc-coated steel sheets |

Advantage

1.All galvanized steel structure Galvanized content up from 275g/sqm to 450g/sqm, good anti-corrosion.

2.Corrosion with over 25years life time

3.100% bolt connection, easy installation

4.Unique concealed steel structure design, to protect column and roof beam no corrosion.

5.PPGI ceiling and wall interior design,easy to cleaning,without sanitary dead angle, give the chicken a healthy growth environment.

6.Unique design 700-800mm hollow roof structure with good insulation , give the ch

7.chicken a comfortable growth temperature.

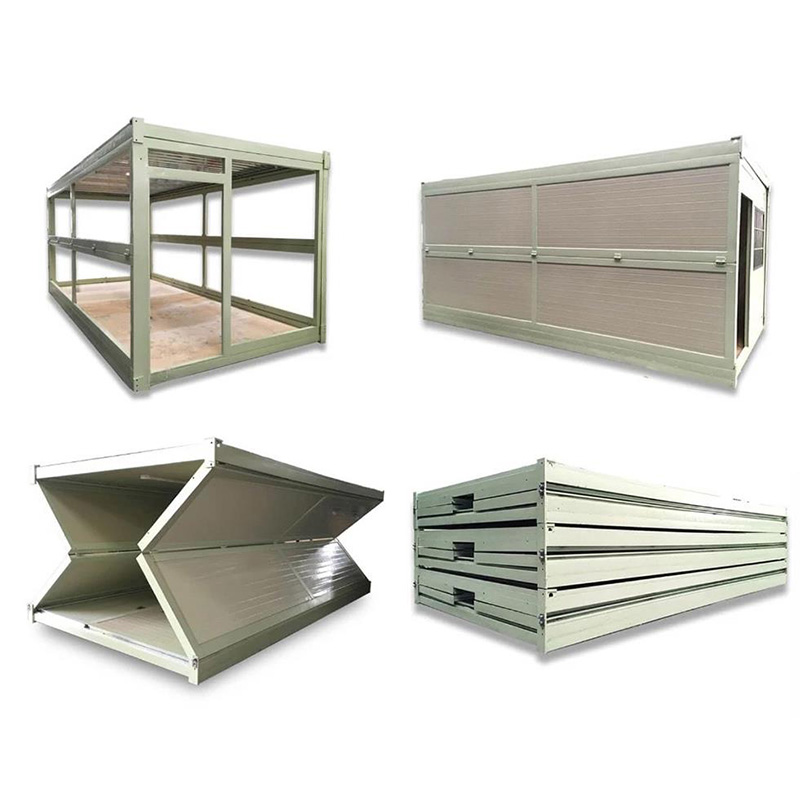

8.Loading capacity 1000sqm/40HQ, saving shipping cost.

9.One 1100sqm standard house installation 18 working days with 6 people

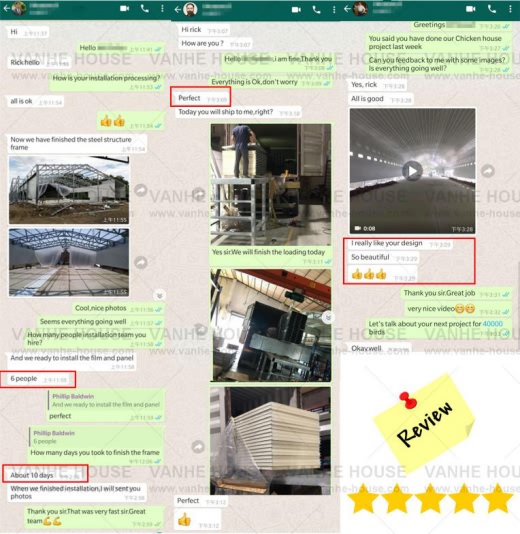

2.Overseas Project & Review

(Over than 2000+projects)

3.Application

Warehouse, temporary office/building, gymnasium, villa, mobile building, guard booth, wall & roof materials for steel building or structure.

4.Our service

1. Professional design and engineering team

The full solution for house design. We could make the design for the whole house as per your requirement.

2. Procurement and Manufacture for all material for prefabricated building

We have a professional procurement team to make sure all the materials are of good quality. And our factory operation under ISO standard, to make sure the fabrication works with high technology.

3. Site management & Installation supervision

We could send our engineers to help with the installation supervision, you just need to prepare a team which knows normal construction works will be OK.

5.FAQ

Q1: What are your main products?

A: Our man products have prefab K house, T house, SHS house, H house, container house, light steel structure villa, steel structure warehouse, sentry box, sandwich panel, and other construction materials.

Q2: What will the client provide before factory offers a good quotation?

A: When we receive an inquiry from a client, client please fills the purchasing intention sheet, providing us with information about house dimensions, draft drawing, layout and materials for the prefabricated house. We will design the drawings and offer a competitive quotation with the above information.

Q3: What are the main materials of the prefabricated house?

A: Our prefabricated house materials mainly include light steel structure, sandwich panel, roof tile, door, window, covers, screws, and other accessories.

Q4: How you calculate the total area?

A: Industry calculation rule as below:

(1) house area = exterior house length X exterior house width X floor

(2) canopy area=exterior house length X 1/2 X canopy width

(3) staircase area = 4.5 sqm X quantity of staircase

(4) corridor area = exterior house length X corridor width

(5) total area = (1) + (2) + (3) + (4) + (5)

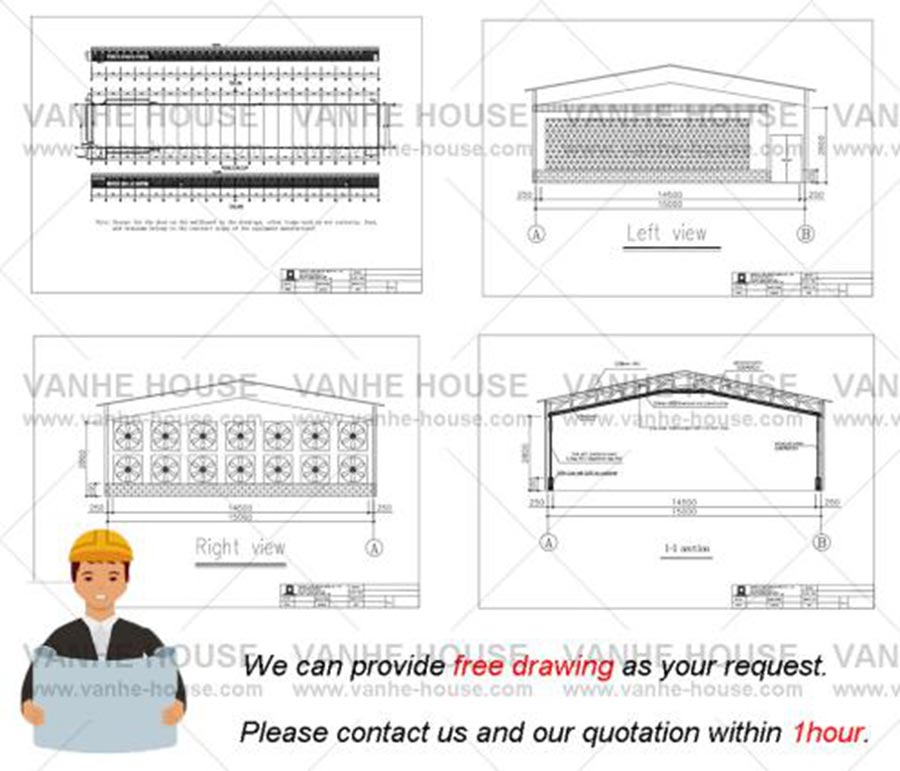

Q5: What drawing of the house will factory supply?

A: Plan drawing, elevation drawing, sectional drawing, foundation drawing, installation drawing.

Q6: How many types of sandwich panel do you have?

A: We have EPS(polystyrene)sandwich panel, rock wool sandwich panel, and PU(polyurethane)sandwich panel.

The characteristics of your sandwich panels respectively:

1. EPS(polystyrene)sandwich panel: Thickness is 50mm, 75mm, 100mm. EPS volume weight is 80-200Kg/m3, water-proof.

2. Rock wool sandwich panel: Thickness is 50mm, 75mm, 100mm. Rock wool volume weight is 200-400Kg /m3, fire-proof, sound-insulation, heat-preservation.

3. PU(polyurethane)sandwich panel: Thickness is 50mm, 75mm, 100mm. PU volume weight is 150-300/m3 water-proof, fire-proof, heat-proof, heat-insulation, heat-preservation, sound-insulation.

Q7: How many colors do your sandwich panels have?

A: Offwhite, ivory white, blue and red color etc…

6.Customized design is welcome, it would be better if you could provide the following information:

1. Location (where will be built? ) _____country, area

2. Size: Length*width*height _____mm*_____mm*_____mm

3. Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

4. Snow load (max. Snow height) _____kn/m2, _____mm

5. Anti-earthquake _____level

6. Brickwall needed or not If yes, 1.2m high or 1.5m high

7. Thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.

8. Door quantity & size _____units, _____(width)mm*_____(height)mm

9. Window quanity & size _____units, _____(width)mm*_____(height)mm

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for Reliable Supplier House Of A Chicken - Hot Sale Large Metal Modern Rain Resistance Steel Structure Chicken Home Poultry House Cow Farm Building – Vanhe , The product will supply to all over the world, such as: Jamaica, Japan, Somalia, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a must for yourself personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We have been confident that we will have a vibrant prospect and to be distributed all over the world in the years to come.

How to Buy a VHCON Prefab House?

Step 1: Initial Enquiry or Display Hall Visit

Start by contacting the VHCON sales team for a no-obligation chat about your project. We’ll walk you through the options, answer any questions, and explain what’s involved with owning a VHCON Modular House.

You can also book a private tour at our Display Hall to view our houses in person.

Whether you’re still planning or ready to move ahead, this first step is all about giving you clarity, confidence, and expert advice from the start.

Step 2: Site Suitability & Pre-Approval Check

Once you’re ready to proceed, we’ll connect you with our trusted Building Certifier and Structural Engineer for a preliminary assessment. Alternatively you can provide your own preliminary assessment from a town planner or building certifier to assess eligibility.

You will need to provide your own site plan to conduct a preliminary assessment. This preliminary assessment helps identify any potential planning restrictions, zoning issues, or site challenges early on — such as setbacks, overlays, wind speed, and climate zone.

This step ensures you have confidence that your project is likely to meet council and building code requirements before moving further into the approvals process.

Step 3: Contract Signing & Initial Deposit

Once your site has been deemed suitable and you’re ready to move forward, we’ll prepare your Build Contract.

This contract will outline:

- The scope of works and what’s included in your Expander Home package

- Customisations (if any) and your selected finishes

- Estimated timeframes for manufacturing, delivery, and installation

- Payment terms, including deposit and progress payments

To secure your place in our production schedule, a non-refundable initial deposit is required upon signing. This deposit confirms your commitment and allows us to begin the next steps — including final plans, engineering, and scheduling your batch build.

Note: We’ll ensure you have ample time to review and understand all contract details, and we’re here to answer any questions before you sign.

Step 4: Factory Construction

Once your contract is finalised, your home enters our scheduled production process. Built in controlled factory conditions by our trusted manufacturing partners, this approach ensures consistent quality, weather protection, and reliable delivery timelines.

The Express Portables design team oversees all aspects of compliance, workmanship, and detail throughout the build. Construction typically takes 9–11 weeks to complete.

Step 5: Shipping, Transport & Delivery

Once factory construction is complete, your home is carefully prepared for shipment. International shipping from our manufacturing facility typically takes 4–5 weeks.

Transport to your site is scheduled in coordination with you or your site builder. Your builder is responsible for unloading the building onto the prepared footings and beginning the installation process.

After installation, the customer is required to arrange the final Occupancy Certificate, with guidance and support provided by our Building Certifier to ensure a smooth approval process.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!