Renewable Design for Modular House Plans - Gable frame light metal building prefabricated industrial steel structure warehouse – Vanhe

Renewable Design for Modular House Plans - Gable frame light metal building prefabricated industrial steel structure warehouse – Vanhe Detail:

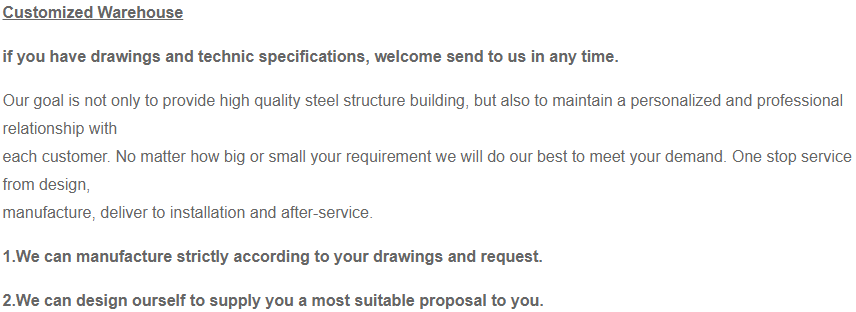

1.Building System

●Higher reliability of steel work. Long using time up to 50 years.

●Steel structure is impact, stable and good anti-seismic of the weight is light.

●Steel structure used for a higher degree of industrialization.

●Steel structures can be assembled quickly and accurately, time saving and labor saving.

●Large interior space of steel structure or steel frame, the max span of prefab steel structure can reach 80meters.

●Likely to cause sealing structure.

●Beautiful appearance: can use different colors and structure.

●Environment friendly: Most of the excess material can be 100% recycled.

●Lower cost and easy maintenance.

●Flexible: can be dismantled and enlarged.

●Manufacture under complete quality control system—ISO9001/ISO14000.

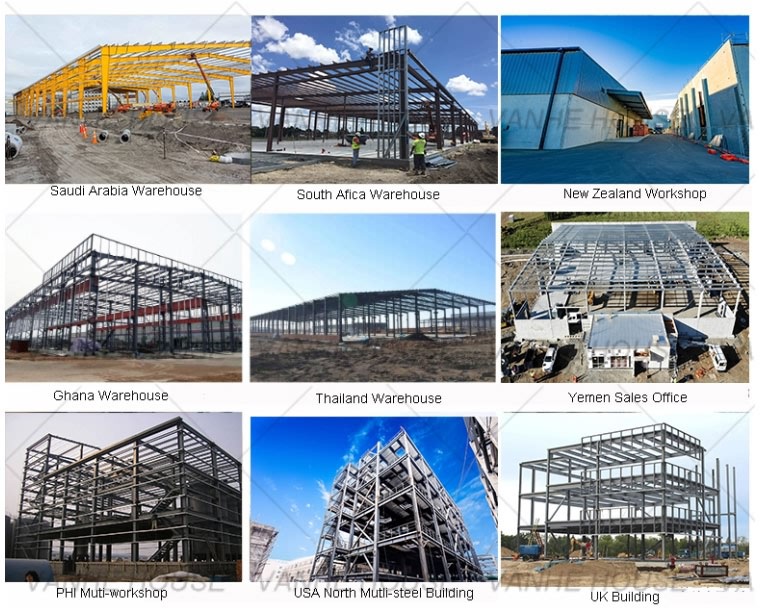

2.Overseas Project

(Over than 2000+projects)

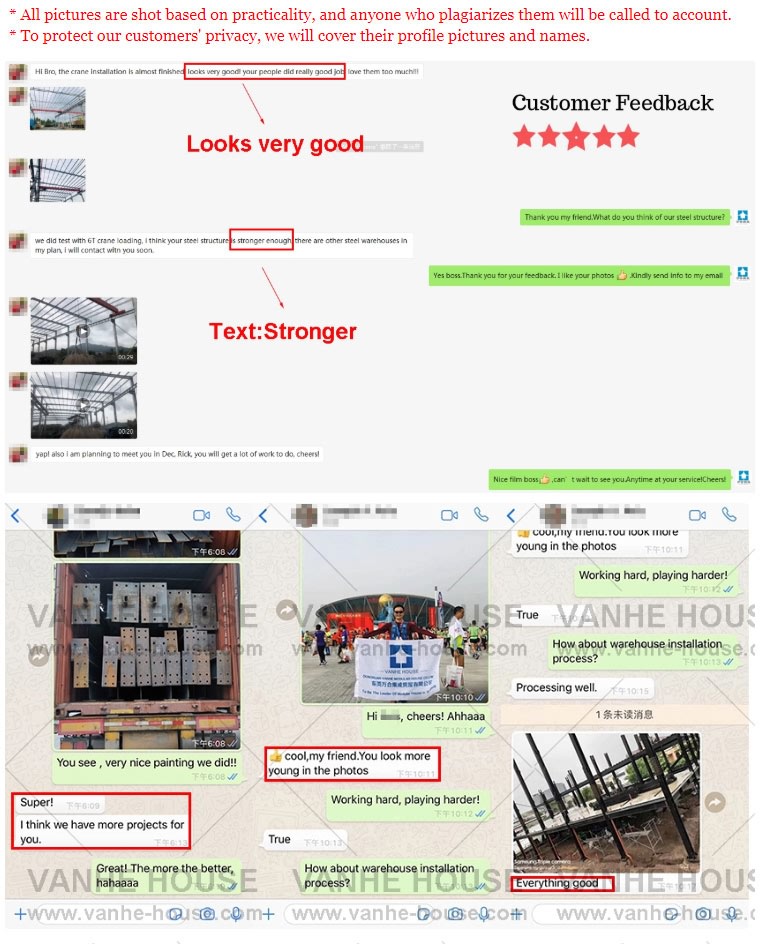

3.Steel Structure Customer Feedback

4.Quote Information

Could you tell me your requirement for your steel structure project?

Basic design requirements and design Load,

1.Project site location:

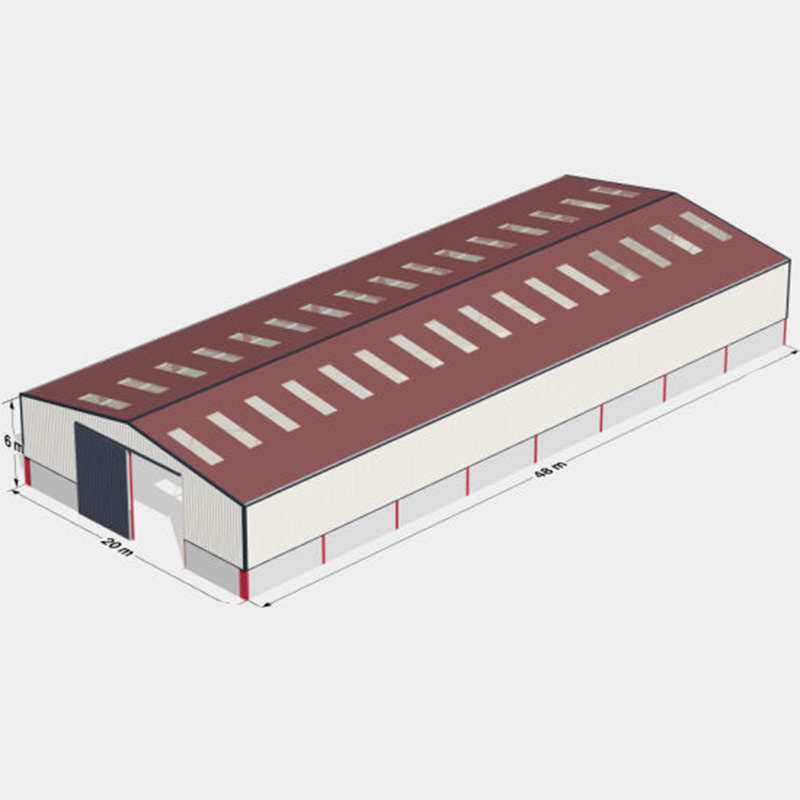

2.Overall dimension (length*width*eave height in meters):

3.Mezzanine or not? How many kgs of load per square meter on mezzanine?

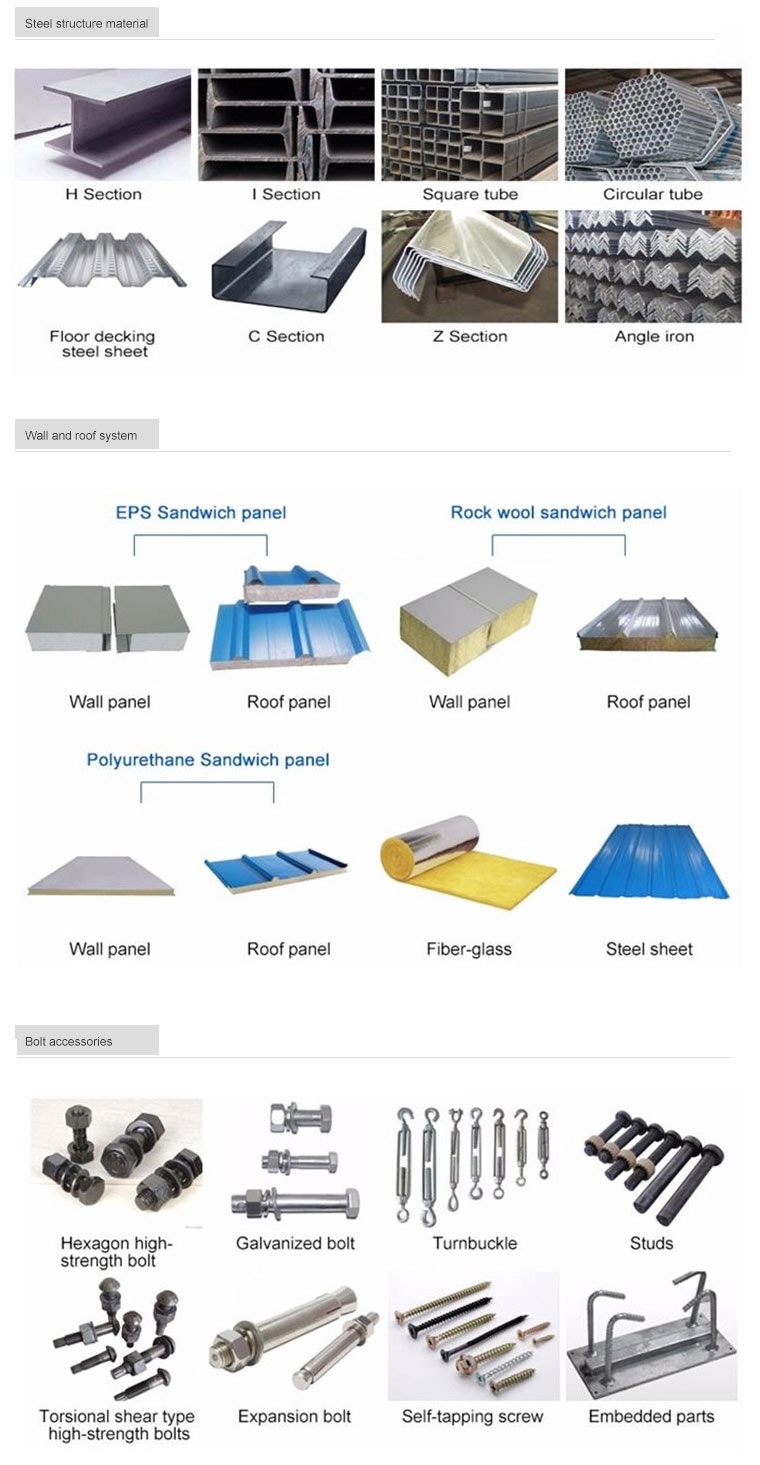

4.Single-layer steel sheet wall or sandwich panel wall:

5.Snow load if applicable:

6.Wind speed/load:

7.Interior column allowed or not:

8.Overhead crane needed or not,capacity?:

9.Any other particular requirements?:

Building Purpose:we will recommend the best design for the purpose of the building

A.Warehouse/Storage

B.Factory

C.Agriculture Barn

D.Retail Store

E.RepairlMechanic Shop

F.Office Space

G. Medical Warehouse

H.Animal Farm (please confirm what kind of animal)

5.Company

6.Packaging&Delivery

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for Renewable Design for Modular House Plans - Gable frame light metal building prefabricated industrial steel structure warehouse – Vanhe , The product will supply to all over the world, such as: Johor, Azerbaijan, Benin, If any item be of interest to you, you should let us know. We will try our best to satisfy your requirements with high quality goods, the best prices and prompt delivery. You should feel free to contact us at any time. We will reply you when we receive your inquiries. Make sure you note that samples are available before we start our business.

How to Buy a VHCON Prefab House?

Step 1: Initial Enquiry or Display Hall Visit

Start by contacting the VHCON sales team for a no-obligation chat about your project. We’ll walk you through the options, answer any questions, and explain what’s involved with owning a VHCON Modular House.

You can also book a private tour at our Display Hall to view our houses in person.

Whether you’re still planning or ready to move ahead, this first step is all about giving you clarity, confidence, and expert advice from the start.

Step 2: Site Suitability & Pre-Approval Check

Once you’re ready to proceed, we’ll connect you with our trusted Building Certifier and Structural Engineer for a preliminary assessment. Alternatively you can provide your own preliminary assessment from a town planner or building certifier to assess eligibility.

You will need to provide your own site plan to conduct a preliminary assessment. This preliminary assessment helps identify any potential planning restrictions, zoning issues, or site challenges early on — such as setbacks, overlays, wind speed, and climate zone.

This step ensures you have confidence that your project is likely to meet council and building code requirements before moving further into the approvals process.

Step 3: Contract Signing & Initial Deposit

Once your site has been deemed suitable and you’re ready to move forward, we’ll prepare your Build Contract.

This contract will outline:

- The scope of works and what’s included in your Expander Home package

- Customisations (if any) and your selected finishes

- Estimated timeframes for manufacturing, delivery, and installation

- Payment terms, including deposit and progress payments

To secure your place in our production schedule, a non-refundable initial deposit is required upon signing. This deposit confirms your commitment and allows us to begin the next steps — including final plans, engineering, and scheduling your batch build.

Note: We’ll ensure you have ample time to review and understand all contract details, and we’re here to answer any questions before you sign.

Step 4: Factory Construction

Once your contract is finalised, your home enters our scheduled production process. Built in controlled factory conditions by our trusted manufacturing partners, this approach ensures consistent quality, weather protection, and reliable delivery timelines.

The Express Portables design team oversees all aspects of compliance, workmanship, and detail throughout the build. Construction typically takes 9–11 weeks to complete.

Step 5: Shipping, Transport & Delivery

Once factory construction is complete, your home is carefully prepared for shipment. International shipping from our manufacturing facility typically takes 4–5 weeks.

Transport to your site is scheduled in coordination with you or your site builder. Your builder is responsible for unloading the building onto the prepared footings and beginning the installation process.

After installation, the customer is required to arrange the final Occupancy Certificate, with guidance and support provided by our Building Certifier to ensure a smooth approval process.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!